How to Prevent Rust: The Critical Role of Passivates and Sealers

December 18, 2025

December 18, 2025

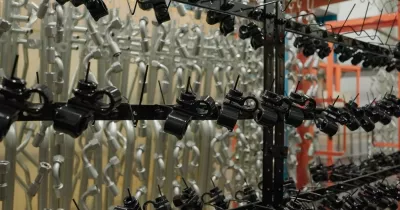

Rust is the silent enemy of metal components. It's a form of corrosion that can lead to structural failure, costly repairs, and a tarnished brand reputation. While selecting the right base metal is the first step, true long-term protection comes from advanced surface treatments. This article will explore the science behind rust formation and detail how a two-step approach using passivates and sealers can provide the ultimate defense against corrosion, ensuring your products stand the test of time.

Understanding Rust and Corrosion

Rust, or iron oxide, forms when iron or its alloys, like steel, are exposed to oxygen and moisture. This electrochemical process can be accelerated by salt, chemicals, and high temperatures. While you can't always control the environment, you can control the surface. The most effective way to prevent rust is to create a barrier that stops oxygen and moisture from reaching the metal.

The First Line of Defense: Passivation

Passivation is a chemical process that enhances the natural corrosion resistance of metals like stainless steel. It uses a nitric or citric acid solution to remove free iron from the surface and create a passive, non-reactive oxide layer. This microscopic film acts as a shield, protecting the underlying metal from corrosive elements.

Key benefits of passivation include the removal of surface contaminants, enhancement of the metal's natural protective properties, and a uniform, clean finish that leaves the part's appearance unchanged. The process is particularly critical after machining or fabrication, when free iron particles may be embedded in the surface. These particles can become initiation sites for corrosion if not removed.

For more on the science behind different forms of metal discoloration, read our article on Why Metal Tarnishing Happens.

The Second Layer of Protection: Sealers

For maximum durability, especially in harsh environments, a sealer is applied over the passivated surface. Sealers are post-treatment coatings that fill in any microscopic pores left in the passive layer, creating an even more robust barrier. They are critical for applications exposed to salt spray, high humidity, or industrial chemicals. Modern sealers are designed to be thin and transparent, maintaining the appearance of the underlying finish while dramatically extending its service life.

Best Practices for Rust Prevention

Implementing a comprehensive rust prevention strategy requires attention to detail at every stage.

The process begins with thorough cleaning to remove oils, grease, and dirt. This ensures the passivate can reach the entire metal surface and form a uniform protective layer. Next, passivation is applied according to the manufacturer's specifications, creating the primary barrier against corrosion. Following passivation, a sealer is applied to fill micropores and add a second layer of defense. Finally, inspection verifies coating integrity and guarantees complete and uniform protection.

Maximize the longevity of your metal components

Preventing rust is not a single action but a systematic process. By combining the power of passivation with the enhanced protection of a sealer, you can create a multi-layered defense that dramatically extends the life of your metal components. This two-step approach is the key to ensuring reliability, safety, and performance in any environment. Don't wait for rust to appear—be proactive with your corrosion protection strategy.

Looking for the best corrosion protection for your parts? Discover Our Advanced Post-Plate Solutions

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.