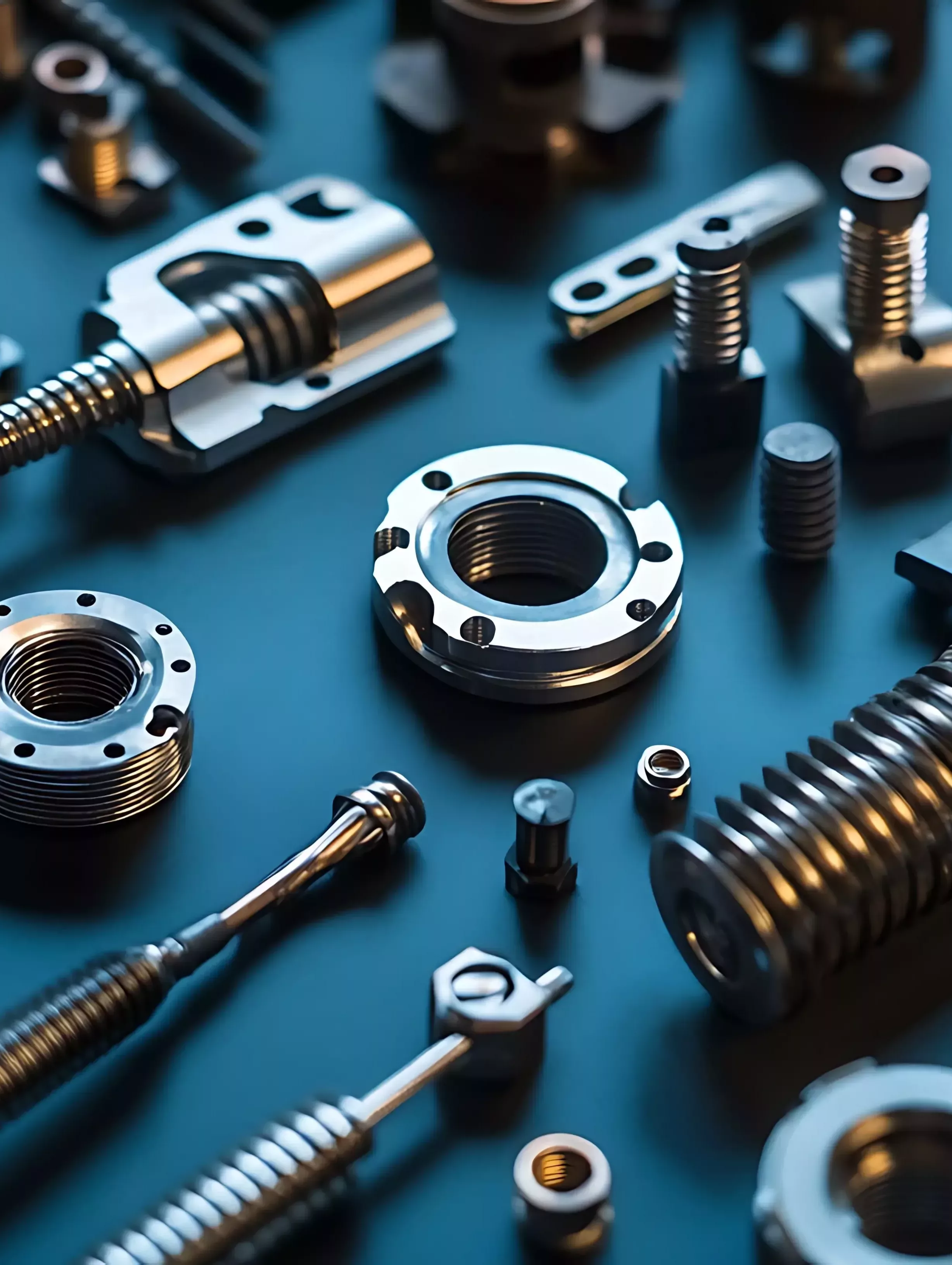

Innovative Coating Technologies for OEM and Tier 1 Excellence

At PAVCO, we empower Original Equipment Manufacturers (OEMs) and Tier 1 suppliers with cutting-edge industrial electroplating solutions that redefine durability, sustainability, consistency, and performance. With over 75 years of experience, PAVCO is your trusted partner in achieving superior finishes tailored to your industry's demands.

Why PAVCO?

Expertise Across Industries

Our coatings cater to a wide range of sectors

Automotive

Enhancing vehicle components with durable, high-performance finishes, including Zinc and Zinc Nickel boosted by our state of the art passivate and sealer technologies. On the decorative side, we offer a full spectrum of trivalent chromium plating processes to achieve aesthetic and performance directives.

Aerospace

Precision coatings that meet stringent safety and performance standards. Our low hydrogen embrittlement zinc nickel formulation and hexavalent chromium free passivates can assist transitions from Cadmium processes.

Agriculture and Hydraulics

Protecting machinery from wear and corrosion in demanding environments with advanced coatings for heavy machinery. Post-plating forming operations such as crimping or bending in hydraulic applications is an important focus for this application.

Consumer Electronics and Appliances

Elevating aesthetics and functionality for global brands that require zinc as an underlayer for powder coating or bright nickel for wired goods among other finishes.

Tools and Hardware

Robust coatings for tools and locking mechanisms. A special attention to our trivalent chromium plating processes including Hex-A-Gone Revolution, a way to electroplate chromium in bulk.

Pioneering Green Industrial Coatings

PAVCO leads the way with eco-friendly approaches to new and established processes. Our commitment to sustainability ensures compliance with environmental standards while maintaining exceptional performance. Clear examples include HyProCoat 630, a sealer developed to be tolerant to acidic drag-in from passivates extending its useful life several times. Smart Zinc Premier using temperature produced by the electrolytic process to increase productivity and reduce raw material usage.

Unmatched Advantages

Sustainability

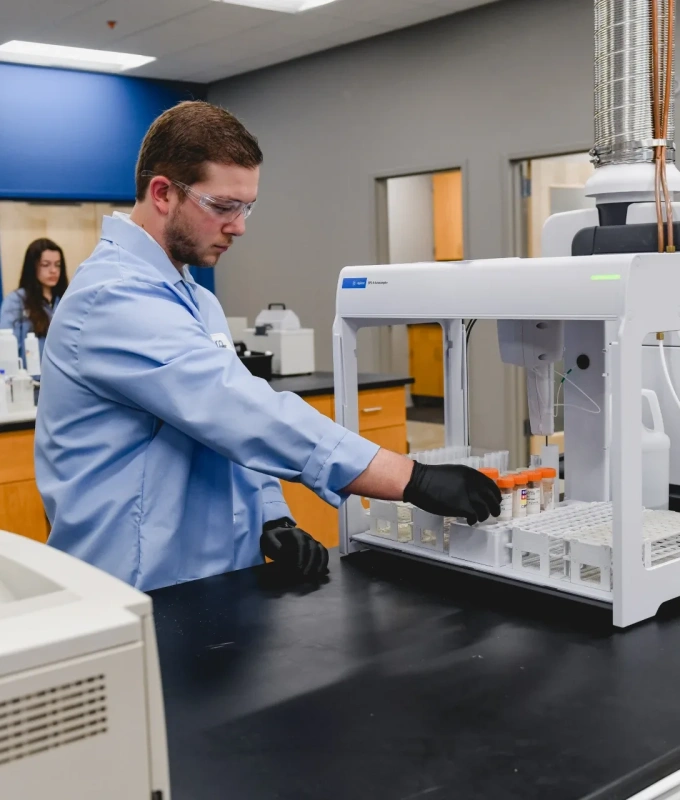

Sustainable, low-energy solutions, cobalt-free post-treatment, trivalent chromium plating. We optimize plating processes through technical collaboration and long-term partnerships, providing continuous technical support, instrumentation analysis and industry best practices.

Innovation

State-of-the-art technologies to meet evolving industry needs, such as anti-corrosion coatings and industrial surface finishes without sacrificing productivity in the supply chain.

Global Reach

Serving key manufacturing clusters throughout the world.

Custom Solutions

Tailored multi layer coatings designed to meet your unique specifications.

Certified QMS

Our Quality Management System has been certified to the ISO 9001:2015 standard.

Ready to elevate your manufacturing processes?

Contact PAVCO now to learn more about how we can help transform your products, consolidate coating specifications or develop next-generation processes for upcoming engineering specifications.