How protective coatings can extend the life of your metals

March 21, 2024

March 21, 2024

Metals are versatile materials used in countless applications, from building infrastructure to crafting household appliances.Protective coatings play a crucial role in safeguarding these valuable assets and extending their lifespan.

This blog post dives into the power of protective coatings and explores how they work to prevent corrosion, maintain aesthetics, and ensure the structural integrity of metal surfaces.

The Three-Layer Armor: How protective coatings work

Protective coatings function as a three-layer defense system that shields metals from various environmental threats. This system includes:

1. Electroplated metal coating: This layer is made of a metal that is more susceptible to corrosion than the underlying base metal.

As this layer corrodes, it sacrifices itself to protect the base metal from the same fate. Different metals offer varying degrees of protection, with zinc, nickel, and copper being common choices due to their unique properties.

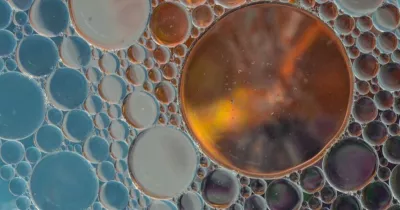

2. Passivate layer: This layer acts like a reinforcement, further strengthening the defense. It is a thin layer formed by a chemical reaction between the electroplated metal and the passivate solution.

This reaction creates an inert surface, meaning it is unreactive and less prone to corrosion. Additionally, the passivating layer acts as a primer for the topcoat, ensuring a strong bond between the two layers.

3. Topcoat: This layer acts like a shield, providing the final line of defense. It acts as a dense barrier, sealing the underlying layers and protecting them from various threats.

Benefits of Using Protective Coatings

Protective coatings offer a multitude of benefits for your metal assets:

Extended lifespan: By preventing corrosion and other forms of deterioration, protective coatings significantly extend the service life of your metals, reducing the need for frequent replacements and saving resources in the long run.

Enhanced aesthetics: Protective coatings come in a variety of colors and finishes, allowing you to maintain the visual appeal of your metal surfaces while protecting them.

Improved performance: By safeguarding metals from environmental factors, protective coatings help to maintain their structural integrity and optimal performance.

Increased sustainability: By extending the lifespan of metals, these coatings contribute to a more sustainable future by reducing waste and the need for resource extraction.

How to achieve the perfect finish?

Transforming raw metal into an object with a sleek, durable, and functional finish requires a meticulous three-step process: pre-plating, plating, and post-plating.

Each stage plays a crucial role in achieving the desired outcome, and PAVCO, a leader in metal finishing solutions for over 75 years, provides the tools you need to excel at each one.

Before coating your metal, ensuring its impeccable cleanliness is crucial. Our extensive line of pre-plate solutions tackles even the most demanding cleaning challenges. Their cleaning agents effectively remove contaminants like grease, oxides, and dirt, allowing for optimal adhesion of the subsequent plating layer.

Choosing the appropriate plating technology depends on various factors, including the desired metal finish, substrate material, and application requirements. Discover our portfolio of plating technologies, including Zinc, Zinc alloys, nickel or trivalent chromium.

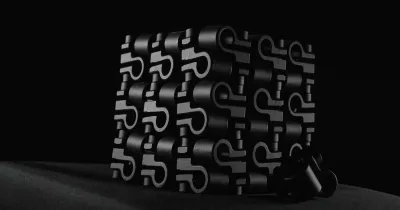

The final step involves applying a protective or decorative coating. Our post-plate solutions offer a variety of options, as seen in the image, such as:

Cobalt-free Trivalent Passivates: Enhance corrosion resistance without the use of cobalt, ensuring an eco-friendly solution.

Trivalent Passivates: Provide a protective layer that enhances the durability and aesthetic appeal of the metal surface.

Black Trivalent Passivates: Offer additional protection against wear, abrasion, or chemicals while providing a sleek black finish.

Sealers/Topcoats: Improve the appearance and durability of the surface with specialized coatings designed for optimal performance.

By using PAVCO's high-quality solutions, you can significantly extend the lifespan and elevate the visual appeal of your metals.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.