Understanding Cathodic Protection: The Role of Sacrificial Coatings

December 18, 2025

December 18, 2025

From massive offshore oil rigs to the steel rebar in a concrete bridge, corrosion is a constant threat. One of the most ingenious methods for fighting this threat is cathodic protection (CP). First discovered in the 1820s, this technique manipulates electrochemistry to protect a metal structure by making it the cathode of an electrochemical cell. This article will explain the fundamentals of cathodic protection and focus on its most common application: the use of sacrificial coatings to prevent corrosion.

The Science of Cathodic Protection

Corrosion is an electrochemical process where a metal gives up its electrons and deteriorates. Cathodic protection works by introducing another, more easily corroded metal into the system. This "sacrificial metal" becomes the anode, giving up its electrons and corroding instead of the structure you want to protect, which becomes the cathode.

There are two main types of cathodic protection. Impressed Current Cathodic Protection (ICCP) uses an external DC power source to force a current from an anode through the electrolyte to the structure. This method is used for large, complex structures like pipelines and offshore platforms where passive protection is insufficient. Galvanic Cathodic Protection, on the other hand, relies on a more electrochemically active metal directly connected to the structure. The natural voltage difference between the two metals drives the protective current without any external power source.

To learn more about the electrochemical principles behind corrosion, read our article on Understanding Galvanic Reactions.

The Power of Sacrificial Coatings

The most common example of galvanic cathodic protection is a sacrificial coating. In this method, a layer of a more active metal is applied over the metal to be protected. This coating serves two purposes: it acts as a physical barrier, preventing oxygen and moisture from reaching the base metal, and it provides cathodic protection if that barrier is breached.

Galvanized Steel: A Perfect Example

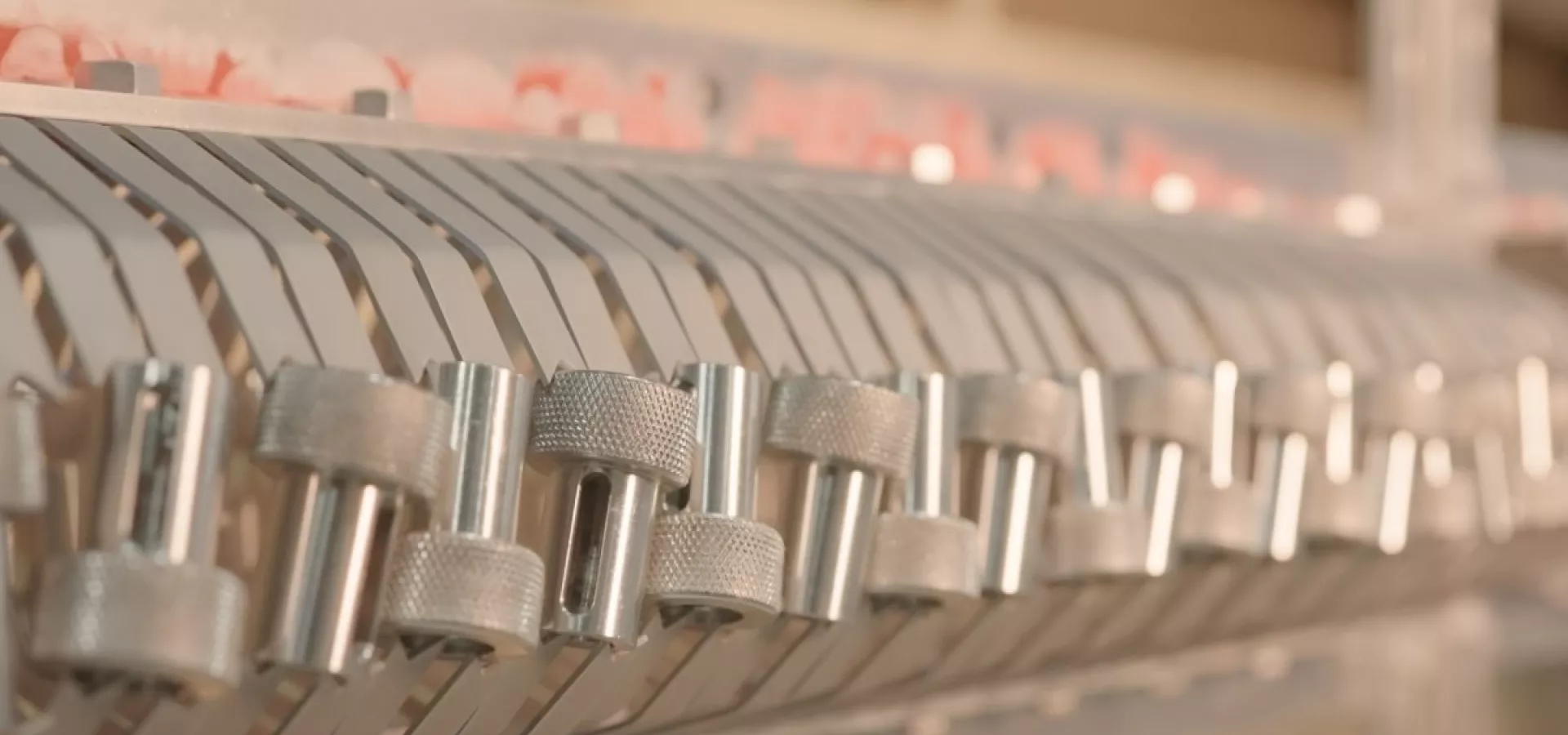

Galvanized steel is steel that has been coated with a layer of zinc. Zinc is more electrochemically active than steel, meaning it has a more negative electrode potential. This relationship is defined by the galvanic series, which ranks metals by their tendency to corrode in a given environment.

Because zinc is more negative, it will corrode first when the two metals are in contact in the presence of an electrolyte (like moisture). Even if the zinc coating is scratched and the steel is exposed, the zinc will continue to act as a sacrificial anode, protecting the exposed steel from rust. This dual-action protection—both barrier and electrochemical—makes galvanized steel one of the most cost-effective and reliable corrosion protection methods available.

Applications of Cathodic Protection

Cathodic protection is used in a wide range of industries and applications. In the oil and gas industry, it protects pipelines, storage tanks, and offshore platforms from corrosion. In infrastructure, it safeguards steel reinforcement bars in concrete bridges and buildings. In the marine industry, it protects ship hulls and port structures. Even household items like water heaters use sacrificial anodes to extend their lifespan.

You can find a closer look at the different types of sacrificial anodes and their applications in our post on Sacrificial Anodes: How They Work.

How do I know if my cathodic protection system is working?

Cathodic protection systems can be monitored using specialized equipment that measures the potential difference between the protected structure and a reference electrode. Regular testing ensures the system is providing adequate protection. For more on testing standards, see our article on the ASTM B571 Standard.

Let’s fight together against corrosion

Cathodic protection is a clever and effective way to win the fight against corrosion. By using a more reactive metal as a sacrificial coating, we can ensure the longevity and structural integrity of critical metal assets. The zinc coating on galvanized steel is a testament to the power of this principle, providing a dual-action defense that combines a physical barrier with electrochemical protection. Understanding this process is key to designing and manufacturing durable, long-lasting metal products.

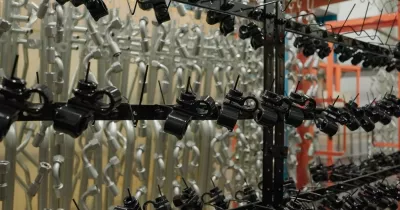

Want to leverage the power of zinc for your products? Explore Our Plating Technologies

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.