Common Metal Polishing Mistakes and How to Avoid Them

December 18, 2025

December 18, 2025

Metal polishing is both an art and a science. When done correctly, it transforms a dull, scratched surface into a brilliant, mirror-like finish. However, the path to a perfect polish is filled with potential pitfalls. From using the wrong tools to applying too much pressure, simple mistakes can ruin a workpiece and waste valuable time.

This guide will walk you through the most common metal polishing errors and provide expert tips on how to avoid them, ensuring you achieve a flawless finish on every project.

The Top 8 Metal Polishing Mistakes

1. Skipping the Cleaning Step

Polishing a dirty surface is the fastest way to create scratches. Any dust, grit, or residue will be ground into the metal by the polishing wheel, causing more harm than good. Even seemingly clean surfaces can harbor microscopic particles that will damage the finish.

The solution is straightforward: always start by thoroughly cleaning the workpiece with a degreaser or appropriate cleaner. Ensure the surface is completely dry before you begin. This simple step can save hours of rework and prevent irreversible damage. For a deeper understanding of surface preparation, read our article on Electrolytic Cleaning Explained.

2. Using the Wrong Polishing Compound

Polishing compounds are not one-size-fits-all. Each is designed for a specific metal and purpose, whether cutting, coloring, or finishing. Using the wrong compound can result in tarnishing, discoloration, or a dull finish that requires additional work to correct.

The solution is to match the compound to the metal. A general rule is to use brown tripoli for cutting and green rouge for finishing on most non-ferrous metals, and a white or blue compound for stainless steel. Always test the compound on a small, inconspicuous area before polishing the entire surface.

3. Applying Too Much Pressure

Excessive pressure generates heat, which can burn or warp the metal, especially on thin parts. It doesn't speed up the process; it just causes damage. Many beginners mistakenly believe that pressing harder will achieve results faster, but the opposite is true. The solution is to let the wheel and the compound do the work. Use light, consistent pressure and keep the workpiece moving. This approach not only prevents damage but also produces a more uniform finish.

4. Skipping Grit Progression

Polishing is a multi-step process. Jumping from a coarse, scratch-removal stage directly to a final finishing stage will leave deep scratches visible. Each grit level removes the scratches from the previous level, so skipping steps means those deeper scratches will remain. The solution is to work your way through progressively finer grits. If you start with a 180-grit sandpaper, move to 220, then 320, and so on, before you even touch a polishing wheel. This methodical approach ensures a truly smooth, scratch-free surface.

5. Over-Polishing the Surface

It is possible to have too much of a good thing. Over-polishing can round over sharp edges, blur details, and even thin the metal. This is particularly problematic on parts with tight tolerances or intricate designs. The solution is to stop and inspect your work frequently. Once you've achieved the desired finish, move on. Knowing when to stop is as important as knowing how to start.

6. Neglecting Safety Precautions

Polishing generates dust, heat, and sometimes fumes, particularly when working with certain compounds or power tools. Ignoring safety measures can put you at risk of injury or long-term health issues. Always wear protective gloves to prevent burns or cuts, use safety goggles to shield your eyes from debris, and work in a well-ventilated area to avoid inhaling potentially toxic fumes.

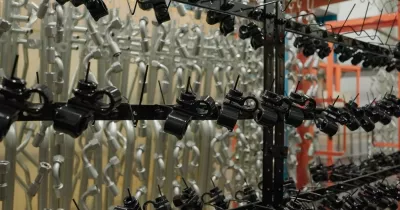

7. Using Contaminated Polishing Wheels

If you use the same buffing wheel for different compounds without cleaning it, you'll transfer abrasives and contaminants from one stage to the next. This can scratch the surface you're trying to polish. The solution is to dedicate specific wheels to specific compounds and clean them regularly with a wire brush.

8. Ignoring Environmental Factors

Environmental factors such as humidity, temperature, and dust can significantly affect polishing outcomes. High humidity can cause rust to form on freshly polished metal, while dust in the air can settle on the surface and cause scratches. The solution is to work in a dry, clean, and temperature-controlled environment. Avoid leaving polished metal in humid areas without applying a protective sealant.

Frequently Asked Questions

What is the difference between buffing and polishing?

Polishing removes scratches and imperfections using abrasive compounds, while buffing enhances the final shine using very fine compounds or clean wheels. Polishing comes first, followed by buffing.

How often should I replace my polishing wheels?

Replace polishing wheels when they become worn, contaminated, or lose their shape. A wheel that is loaded with compound residue or has hardened sections will not perform effectively and can damage the workpiece.

Can I polish aluminum the same way I polish stainless steel?

No, aluminum is softer than stainless steel and requires different compounds and techniques. Use compounds specifically designed for aluminum and apply less pressure to avoid removing too much material.

Is it necessary to polish before plating?

Yes, proper polishing is essential before plating. The plating will replicate the surface finish of the base metal, so any scratches or imperfections will be visible in the final product. This is a critical step in Quality Control in Plating.

Achieve a professional metal finish

Achieving a professional metal polish requires patience and attention to detail. By avoiding these common mistakes, you can save time, prevent damage, and produce a consistently brilliant finish. Remember to start clean, use the right materials, apply a gentle touch, and follow a logical progression. With practice, these best practices will become second nature, and your results will speak for themselves.

Need to ensure your parts are perfectly prepared for plating? Check Out Our Pre-Plate Solutions

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.