Chrome Alternatives: Learn How to Select the Right Finish

December 18, 2025

December 18, 2025

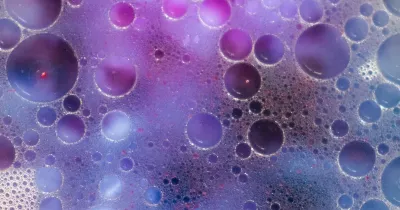

For decades, hexavalent chromium has been the go-to for a bright, durable, and corrosion-resistant finish. However, significant environmental and health concerns have led to strict regulations, pushing the industry toward safer alternatives. The challenge is to find a finish that not only complies with new standards but also delivers the performance and aesthetic qualities that modern applications demand. This article explores the leading chrome alternatives, helping you understand the options and select the best finish for your needs, balancing performance, compliance, and cost.

The Problem with Hexavalent Chromium

Hexavalent chromium is a known carcinogen, and its use is heavily regulated by bodies like OSHA and the EPA. The electroplating process for Cr VI is inefficient and produces hazardous air pollutants and waste. As a result, many industries are actively seeking to replace it with more sustainable solutions. The most prominent alternative is its less toxic cousin, trivalent chromium.

Trivalent Chromium:The Compliant Successor

Trivalent chromium plating is over 500 times less toxic than hexavalent and is not classified as a carcinogen. It offers a comparable, slightly darker finish and excellent performance characteristics. PAVCO's HyPro™ line of compliant chemistries includes advanced trivalent passivates that provide robust corrosion protection and meet the stringent requirements of REACH and RoHS.

If you are currently using hexavalent chromium, it is crucial to understand the chemical differences and the benefits of switching. For a deep dive into the chemistry and benefits of trivalent chromium, read our post on Hexavalent vs Trivalent Chromium.

How to Choose the Right Finish

Selecting the right alternative depends on several factors. First, consider the corrosion resistance requirements. How harsh is the end-use environment? Will the part be exposed to salt spray, chemicals, or extreme temperatures? Second, evaluate the appearance needs. What color, brightness, and reflectivity are required? Does the finish need to match existing components? Third, assess the cost implications. What is the budget for the finishing process, including both material and labor? Finally, ensure compliance with relevant regulations. Are there specific industry standards (such as automotive, aerospace, or medical device) that must be met?

If your application is in the automotive sector, you can see how the industry is adopting safer finishes in our article on Automotive Coatings.

What is the main difference between hexavalent and trivalent chromium?

Hexavalent chromium (Cr VI) is highly toxic and carcinogenic, while trivalent chromium (Cr III) is significantly less toxic and environmentally friendly. Trivalent chromium is the preferred choice for modern, compliant finishing operations.

Can trivalent chromium provide the same corrosion protection as hexavalent?

Yes, modern trivalent chromium passivates can provide comparable or even superior corrosion protection when properly applied and sealed. The key is selecting the right chemistry for your specific application.

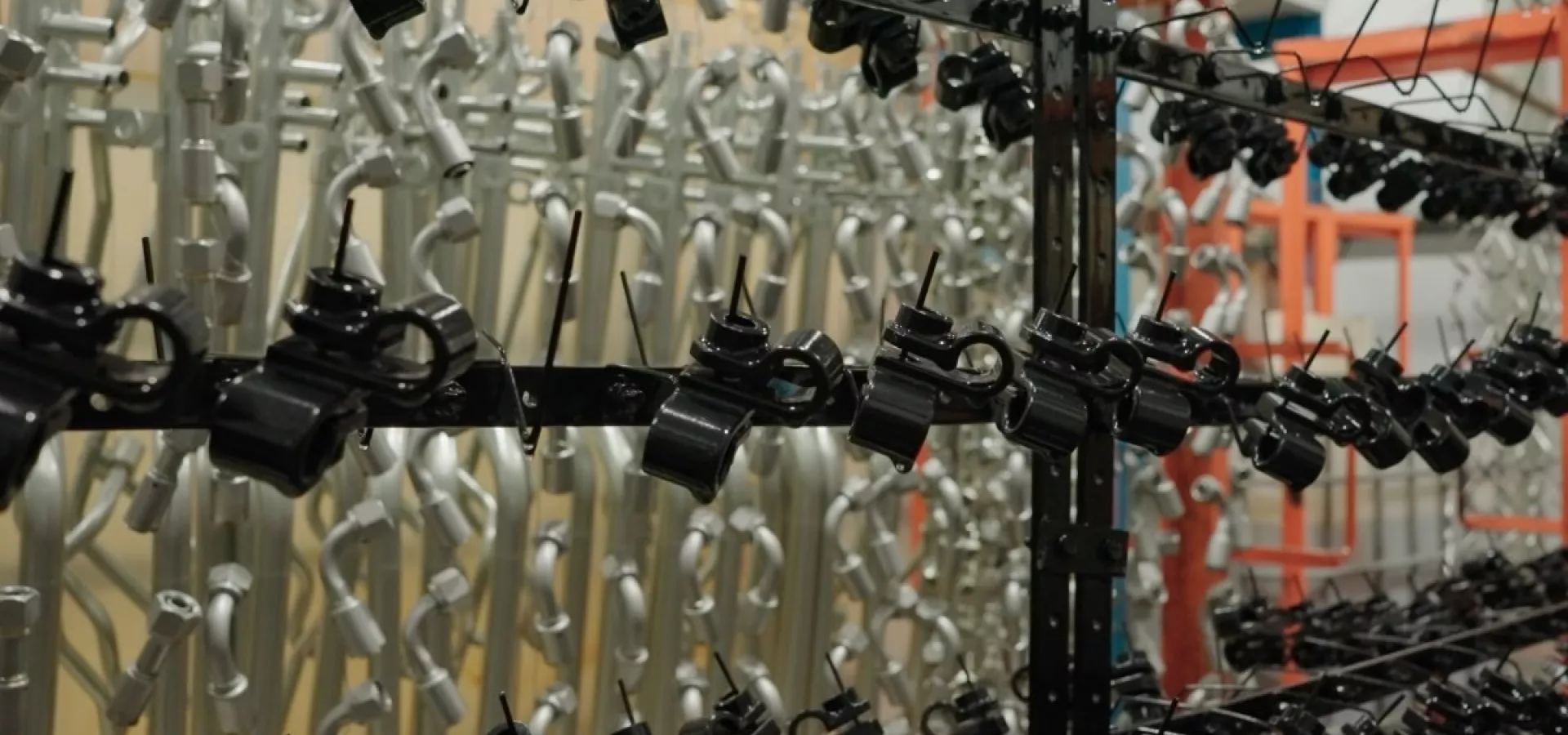

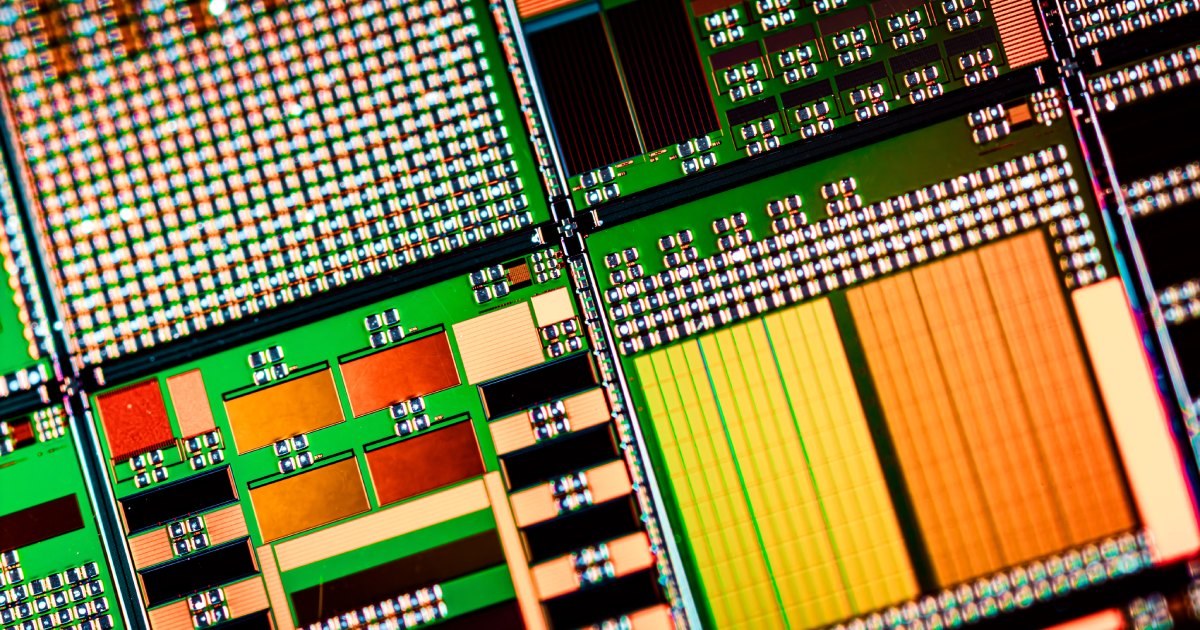

What industries are moving away from hexavalent chromium?

Automotive, aerospace, electronics, and consumer goods industries are all actively transitioning to safer alternatives due to environmental regulations and worker safety concerns. To understand the regulatory landscape impacting the industry, we recommend reading our post on REACH Compliance in Metal Finishing.

How do I know which finish is right for my application?

Consult with a metal finishing expert who can evaluate your specific requirements, including corrosion resistance, appearance, cost, and regulatory compliance. PAVCO's technical service team can help you select the optimal solution.

We offer a full range of innovative plating solutions that can meet your new compliance requirements. Discover PAVCO's full range of innovative plating solutions.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.