Choosing the Best Cleaner for Optimal Surface Preparation

January 06, 2025

January 06, 2025

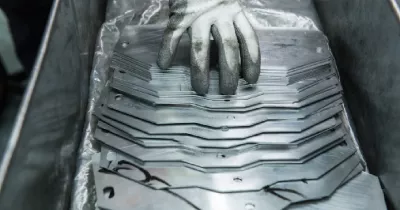

In the world of metal finishing, surface preparation is a critical step that can impact the quality of the final product. Whether you're dealing with automotive parts, industrial machinery, or decorative items, the importance of removing oils, rust, and dirt cannot be overstated. These contaminants can compromise adhesion and lead to defects, ultimately affecting the durability and aesthetics of the finished product.

In this blog post, we will explore the different types of cleaners available for surface preparation, the key considerations for choosing the right cleaner, and how Pavco’s solutions can meet your needs.

The Importance of Surface Preparation

Surface preparation is the foundation of any successful metal finishing process. It involves cleaning the metal surface to remove any contaminants that might interfere with the adhesion of coatings or paints. Oils, rust, and dirt are common culprits that can cause defects such as peeling, blistering, or corrosion. By ensuring a clean and contaminant-free surface, you can enhance the performance and longevity of the finished product.

Types of Cleaners

Choosing the right cleaner is crucial for effective surface preparation. There are several types of cleaners, each with its own advantages and limitations.

Solvent-Based Cleaners

Solvent-based cleaners are highly effective at removing oils and grease. They work by dissolving the contaminants, making them easy to wipe away. However, these cleaners often contain volatile organic compounds (VOCs), which raise environmental concerns due to their contribution to air pollution and potential health risks.

Aqueous Cleaners

Aqueous cleaners are water-based and considered more eco-friendly compared to solvent-based options. They are effective at removing a variety of soils but typically require rinsing and drying to prevent water spots or corrosion. Aqueous cleaners are suitable for applications where environmental impact is a concern.

Alkaline Cleaners

Alkaline cleaners are designed for heavy-duty cleaning tasks, such as removing thick grease or rust. They are commonly used in industrial applications where robust cleaning is required. These cleaners are effective, but must be chosen carefully to avoid damaging sensitive metals.

Acidic Cleaners

Acidic cleaners are ideal for removing rust and scale, particularly on steel surfaces. They work by dissolving the oxides, leaving a clean and smooth surface. However, caution must be exercised to prevent over-etching or damage to the metal.

Key Considerations for Choosing a Cleaner

When selecting a cleaner for surface preparation, several factors must be considered to ensure optimal results.

Metal Type

Different metals react differently to various cleaning agents. It's essential to choose a cleaner that is compatible with the metal you are working with to avoid damage. For instance, acidic cleaners may be too harsh for aluminum but suitable for steel.

Contaminants

The type of soil present on the metal surface will dictate the choice of cleaner. Oils and grease may require solvent-based or alkaline cleaners, while rust might necessitate an acidic cleaner.

Cleaning Method

The method of application—whether immersion, spray, or ultrasonic—can impact the effectiveness of the cleaner. Some cleaners are designed for specific methods and may not perform well if used incorrectly.

Environmental Impact

With increasing regulations on chemical use, the environmental impact of cleaners is a significant consideration. Aqueous cleaners are generally more environmentally friendly, while solvent-based cleaners may face more restrictions due to VOC emissions.

Cost

While initial costs are important, it's also crucial to consider the overall cleaning efficiency and long-term benefits. A more expensive cleaner that provides superior results and reduces rework can be more cost-effective in the long run.

PAVCO's Cleaning Solutions

PAVCO has been a trusted name in the metal finishing industry since 1948, delivering innovative chemical technologies designed for efficiency, reliability, and sustainability. Our commitment to advancing pre-plating, plating, and post-plating processes ensures you have access to comprehensive solutions that address every stage of metal finishing.

PAVCO's PavPrep™ and Clean-R™ solutions are specifically designed to address these challenges. Whether you need to tackle heavy rust or optimize cleaning efficiency, these products provide innovative approaches to maintain the integrity of your surface preparation process. Explore how these solutions can redefine your pre-plating success by exploring our pre-plate solutions.

Elevate your surface preparation process with products that are engineered to exceed expectations. Discover how PAVCO can transform your operations by knowing all of our solutions.

Trust PAVCO to provide not only the products, but also the expertise to guide you through the complexities of metal finishing. Contact us today to take your surface preparation process to the next level.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.