How Waterproof Coatings Protect Your Metal Components

September 24, 2025

September 24, 2025

When it comes to metal, water is often the primary enemy. From the gradual creep of rust on an automotive part to the performance failure of a critical industrial component, moisture and corrosion can wreak havoc. While the term "waterproof" might bring to mind thick, rubbery layers, the world of industrial metal finishing has a far more sophisticated solution: advanced hydrophobic coatings.

In this post, we'll explore how these specialized coatings work, why they are more than just a simple barrier, and how they protect the integrity and lifespan of your essential metal components.

Beyond Simple Barriers: The Science of Hydrophobic Coatings

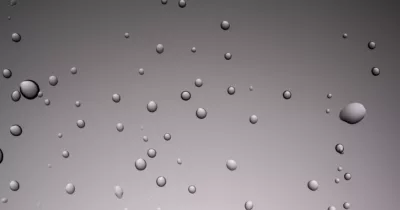

Instead of just "waterproofing," the goal in high-performance finishing is to create a hydrophobic surface. Think of how water beads up and rolls off a freshly waxed car—that's a hydrophobic effect in action. It’s an active repulsion of water, not just a passive blocking of it.

This is achieved through specialized chemical formulations that, when applied to a metal surface, create a low-energy, non-polar surface. Water, being a polar molecule, has very little to "grab onto" and is effectively repelled, minimizing contact time and preventing the chemical reactions that lead to corrosion.

These aren't paints or thick sealants; they are micro-thin chemical layers engineered to bond with the metal surface, offering protection without altering component dimensions or weight significantly. This is a critical factor in industries where precision is everything.

The Plating and Coating Synergy: A Two-Step Process for Maximum Protection

A high-performance hydrophobic coating doesn't work in isolation. It’s the final, crucial step in a comprehensive surface protection strategy. For maximum effectiveness, these topcoats are applied over a foundational layer of electroplated metal.

The Foundation: Zinc and Zinc-Nickel Plating: The process starts by electroplating the part with a sacrificial layer, typically Zinc (Zn) or a Zinc-Nickel (Zn-Ni) alloy. This initial plating provides the primary layer of corrosion defense. Zinc-Nickel, in particular, offers exceptional resistance, making it a go-to choice for demanding applications in the automotive and aerospace sectors.

The Finisher: The Hydrophobic Topcoat: This is where products like PAVCO’s HyProCoat™ formulations come into play. These are engineered to create a synergistic bond with the underlying passivate and zinc or zinc-nickel layer, sealing it from the elements and creating that powerful water-repellent, hydrophobic surface.

This three-step system ensures a multi-layered defense that is far more durable and reliable than a single coating alone.

Ready to build a better defense against corrosion? Explore our industry-leading Plating Technologies that create the perfect foundation for lasting protection.

The Business Benefits: Why This Matters for Your Products

Integrating a robust plating and hydrophobic coating system into your production delivers tangible returns for your business and your customers.

Extended Component Lifespan: By effectively stopping corrosion before it can start, your parts last longer, even in harsh environments. This means fewer warranty claims and a stronger reputation for quality.

Enhanced Reliability and Performance: For critical components, failure is not an option. A hydrophobic surface ensures that performance is not compromised by rust or environmental degradation.

Meeting and Exceeding Standards: Many industries require parts to pass stringent salt spray and corrosion resistance tests. An engineered system of plating and a high-performance topcoat is the most reliable way to meet these specifications.

Protecting your components from moisture requires a modern, scientific approach. By moving beyond simple "waterproofing" and embracing an engineered system of plating and hydrophobic topcoats, you can ensure your products deliver the durability and performance your customers demand.

If you’re looking to elevate the corrosion resistance and performance of your metal components, our team is here to help.Contact us today to discuss how our HyProCoat™ solutions can be tailored to your specific application.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.