Mastering pH Control: Enhancing Electroplating Efficiency

October 02, 2025

October 02, 2025

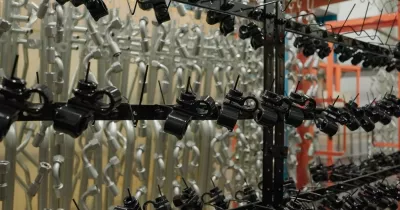

In the world of metal finishing, precision is everything. Achieving a flawless, durable, and consistent finish requires careful control over a multitude of variables. Among the most critical, yet often underestimated, is pH control. For any electroplating process, maintaining the correct pH isn't just a recommendation—it's the bedrock of an efficient and successful operation. An imbalanced pH can quickly derail production, leading to rejected parts, wasted resources, and lost profits.

The Critical Impact of Minor pH Fluctuations

Even small shifts in the pH of a plating bath can have major consequences. A slight deviation can cause a significant drop in plating efficiency. More dramatically, it can lead to the precipitation of valuable bath components, rendering them useless and contaminating your tank. This is especially true for complex processes involving alloys.

Consider Zinc-Nickel (Zn-Ni) plating, a process prized for its exceptional corrosion resistance. In these systems, pH is the master controller of the alloy's composition. A minor adjustment can drastically alter the ratio of zinc to nickel being deposited on the part. To meet strict industry specifications, the pH must be maintained within a very narrow range. Without precise pH control, consistency is impossible.

The Risks of Manual Adjustments

Many operations still rely on manual pH adjustments, but this approach is fraught with risk. It often leads to "over-adds" or, conversely, "missed adds," where a technician either adds too much adjustment chemical or forgets an addition entirely. These errors can cause catastrophic swings in the bath's chemistry.

Furthermore, using the wrong pH-adjusting chemical can be a costly mistake. An improper chemical can introduce contaminants that require hours or even days to remove. In the worst-case scenario, the entire bath may need to be dumped and remade, resulting in significant downtime and material cost. Partnering with an expert can help you avoid these pitfalls.

At PAVCO, our technical service team can help you select the precise chemistries to maintain optimal bath performance. Contact us now!

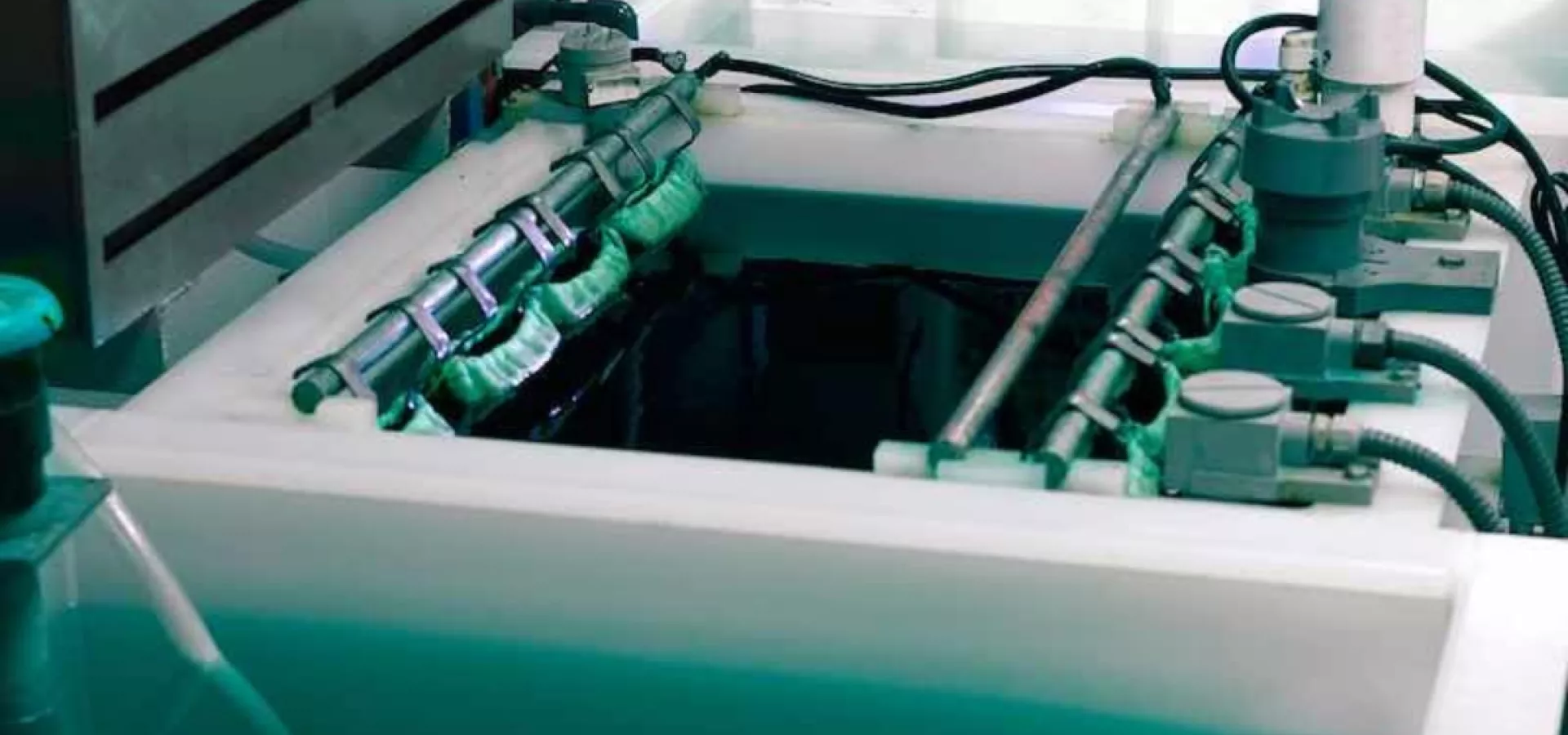

pH Control in Passivates: The Key to Corrosion Resistance

The importance of pH control extends beyond the plating tank and into post-treatment processes like passivation. The pH of a passivate solution directly impacts the final product's corrosion resistance, color, and finish. An incorrect pH can lead to a drastic loss of corrosion protection or undesirable color changes. It can even cause the dissolution of the freshly plated metal, leading to contamination of the passivate bath.

Accurate pH readings in passivates also present a unique challenge. Many passivate solutions contain fluoride, which can damage standard pH probes. This necessitates the use of specialized, fluoride-resistant probes to ensure accurate measurements.

The Smart Solution: Automated pH Controllers

So, how can you eliminate the guesswork and ensure your pH remains perfectly stable? The answer is automation. Modern pH controllers are designed to monitor your bath in real-time and make precise, automatic additions of adjustment chemicals. By keeping the pH within a tight, predefined window, these systems offer a multitude of benefits:

Drastically reduce scrap and rework, saving valuable time and money.

Ensure consistent quality and adherence to specifications for every part.

Optimize chemical consumption by preventing over-adds.

Free up your technicians to focus on other critical tasks.

Implementing an automated pH control system is an investment in quality and efficiency. It transforms a critical variable from a constant worry into a controlled, reliable aspect of your production line.

Ready to take control of your plating process?Discover our advanced solutions and achieve your business goals.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.