Understanding the Impact of Cationic Surfactants on Plating Quality

October 02, 2025

October 02, 2025

In the world of metal finishing, the pursuit of a flawless, high-performance plated surface is paramount. Achieving that perfect balance of brightness, adhesion, and durability requires precise control over countless variables within the plating bath. Among the most critical—and often misunderstood—of these are the chemical additives, specifically cationic surfactants.

While they are essential for modern plating processes, their impact can be a double-edged sword. Understanding how cationic surfactants function is the first step to harnessing their benefits and avoiding potential pitfalls.

What Exactly Are Cationic Surfactants?

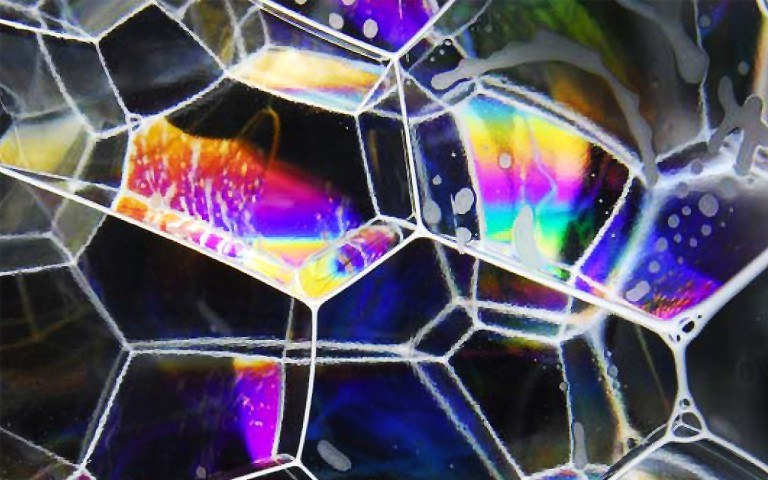

Let's break it down. A "surfactant" (a contraction of "surface-active agent") is a compound that lowers the surface tension between a liquid and a solid. Think of how soap helps water wash away grease—that's a surfactant at work.

The "cationic" part refers to the surfactant's molecular structure. These molecules have a positively charged "head" and a long, uncharged "tail." In an electroplating bath, this is incredibly significant. The part you are plating (the cathode) carries a negative charge, and as opposites attract, the positively charged heads of cationic surfactants are naturally drawn to the workpiece's surface.

This attraction is the key to their power. They migrate to the cathode surface and influence how metal ions are deposited.

The Benefits vs. The Risks

When managed correctly, cationic surfactants are instrumental in achieving superior plating quality. However, when their concentration is out of balance, they can be the root cause of serious defects.

Key Benefits:

Grain Refinement: By adsorbing onto the surface, they act as blocking agents that prevent large, irregular metal crystals from forming. This forces the growth of smaller, more tightly packed grains, which results in a brighter, more uniform, and less porous deposit.

Improved Wetting: They ensure the plating solution fully and evenly contacts the substrate, preventing defects like pitting and improving adhesion, especially on complex parts.

Enhanced Throwing Power: In some formulations, they can help modify the electrochemical potential at the surface, encouraging more uniform metal deposition across both high and low-current-density areas.

Potential Challenges:

Brittleness: An excess of cationic surfactants can co-deposit into the plated layer, creating internal stress and causing the deposit to become brittle and prone to cracking.

Poor Adhesion: Too high a concentration can form a film on the substrate that interferes with the metallurgical bond between the base metal and the plated layer, leading to peeling or flaking.

The PAVCO Approach: Formulation is Everything

Simply adding a cationic surfactant to a bath isn't a solution; it's a gamble. The secret lies in sophisticated formulation, where different additives are balanced to work in synergy.

At PAVCO, our research and development team doesn't just select surfactants; we engineer complete additive systems. Our proprietary chemistries are designed to maximize the grain-refining benefits of specialized surfactants while incorporating other components that mitigate the risks of brittleness and poor rinsing. This holistic approach ensures you get a brilliant, durable finish consistently.

Striving for a more stable and predictable plating bath? Explore our innovative finishing solutions to see how our balanced chemistries can elevate your quality.

How to Maintain Control and Ensure Quality

Managing the impact of cationic surfactants comes down to process control. A brilliant finish on Monday can become a rejected batch by Friday if the bath chemistry isn't properly maintained.

Regular Bath Analysis: Chemical analysis is non-negotiable. Regularly tracking the concentration of your additives is the only way to prevent them from falling too low or climbing too high.

Hull Cell Testing: This classic tool remains one of the best ways to visually assess the condition of your plating bath. It can reveal the effects of an imbalanced surfactant concentration before it impacts your production line.

Work with Your Supplier: Your chemical supplier should be your partner in quality. A good partner provides more than just a drum of chemicals; they provide the technical expertise to help you troubleshoot issues and optimize your process for peak performance.

Are you facing unexplained issues like brittleness, pitting, or poor adhesion? The problem could lie in your bath's organic additives. Contact a PAVCO technical expert today for a no-obligation consultation to help diagnose the issue.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.