5 Key Quality Control Checkpoints for Consistent Plating Results

September 24, 2025

September 24, 2025

In the world of metal finishing, consistency isn't just a goal; it's the bedrock of your reputation. A high-quality, durable finish builds trust with your customers, reduces costly rejects, and ensures your products perform reliably in the field. However, achieving that perfect finish batch after batch can be a significant challenge. From fluctuating chemical baths to subtle changes in operating parameters, many variables can stand in the way of consistency.

The key to overcoming these challenges lies in a robust quality control program. By implementing strategic checkpoints throughout your plating process, you can move from reactive problem-solving to proactive quality assurance. Here are five critical checkpoints that will help you deliver consistent, high-quality results every time.

1. Pre-Treatment and surface preparation

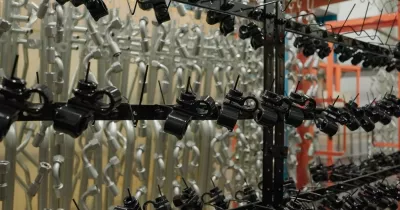

You can't build a strong house on a weak foundation, and you can't achieve a flawless finish on a poorly prepared surface. The pre-treatment stage—where parts are cleaned of oils, soils, and oxides—is arguably the most critical step in the entire plating process. Any residue left on the substrate can cause adhesion failures, blistering, or uneven coating.

Key Quality Control Focus Areas

Visual Inspection: Are parts completely free of visible soils or water breaks after cleaning?

Cleaner Concentration: Regularly titrate your cleaning baths to ensure they are within the specified concentration range.

Temperature & Time: Verify that bath temperatures and immersion times align with your technical data sheets for optimal activation.

A pristine surface is the essential first step for superior plating adhesion. Partnering with a provider that understands the nuances of surface preparation is crucial. Explore PAVCO's advanced pre-treatment and cleaning solutions to ensure your process starts with an impeccably prepared foundation.

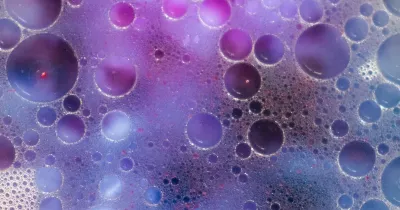

2. Chemical bath concentration and purity

The plating bath itself is the heart of your operation. The chemical composition must be precisely maintained to ensure consistent deposit properties, thickness, and appearance. Even minor deviations in the concentration of primary metals, brighteners, or additives can have a major impact on the final result.

Key Quality Control Focus Areas

Regular Analysis: Implement a strict schedule for chemical analysis, using methods like titration or atomic absorption (AA) spectroscopy.

Additive Dosing: Use properly calibrated dosing pumps and track addition rates carefully. Avoid "add-by-eye" practices.

Impurity Control: Monitor for common metallic impurities (like iron, copper, and lead) that can build up over time and negatively affect the deposit.

Maintaining optimal bath performance requires both diligent in-house testing and high-purity, stable chemistries. The quality of the chemical technology you use is directly linked to the predictability of your results.

3. Operating Parameters: The Plating "Recipe"

If the chemical bath is the heart of the process, then your operating parameters are the recipe. Temperature, pH, agitation, filtration, and—most importantly—rectifier settings (current density or voltage) must be tightly controlled.

Key Quality Control Focus Areas

Rectifier Calibration: Ensure your rectifiers are calibrated and provide accurate, ripple-free DC current.

Temperature & pH: Use calibrated probes to continuously monitor bath temperature and pH levels.

Load Size & Racking: Standardize load sizes and racking configurations to ensure consistent current distribution across all parts.

Inconsistent parameters lead to inconsistent plating thickness and performance. For complex applications, achieving this balance can be challenging. This is where expert support becomes invaluable. The PAVCO technical team collaborates with finishers to dial in the perfect parameters for our plating technologies, helping you optimize efficiency and quality simultaneously.

4. Post-Treatment Application

The job isn't finished once the part comes out of the plating bath. Post-treatment processes like passivates, sealants, and topcoats are what provide critical corrosion resistance and determine the final appearance. Applying these layers correctly is essential to meeting demanding industry specifications (e.g., automotive or aerospace).

Key Quality Control Focus Areas

Immersion Time & pH: Control immersion times precisely, as this often determines the color and protective properties of the passivate. Monitor the pH, as it can drift during production.

Drying & Curing: Ensure parts are dried and cured at the recommended temperatures and times to properly set the post-treatment film. Rushing this step can compromise corrosion protection.

Choosing the right post-treatment is key to meeting your customers' performance requirements. Whether you need a high-performance trivalent passivate or a sealer to extend salt spray testing hours, the right chemistry makes all the difference. Discover our HyPro™ series of high-performance passivates to see how you can elevate your product's durability.

5. Final Inspection and Testing

The final checkpoint is your last opportunity to catch any deviations before the product reaches your customer. This step validates that all previous checkpoints were successful and that the finished product meets all required specifications.

Key Quality Control Focus Areas

Adhesion Testing: Perform standardized tests (e.g., tape test, bend test) to verify the coating is properly adhered to the substrate.

Thickness Measurement: Use X-ray fluorescence (XRF) or magnetic induction tools to confirm that the plating thickness is within the specified range across the part.

Corrosion Resistance: Conduct salt spray testing (ASTM B117) or other corrosion tests as required by the customer to validate the performance of the complete finishing system.

Your Partner in Quality

Achieving consistent, high-quality plating results is a continuous process of monitoring and refinement. By establishing these five key quality control checkpoints, you can build a more robust, reliable, and profitable finishing operation.

At PAVCO, we are more than just a chemical supplier; we are your partner in quality. We provide the innovative technologies and expert technical support you need to optimize every step of your process.

An additional valuable assessment is provided by the Automotive Industry Action Group (AIAG). The CQI-11 internal plating system assessment is a comprehensive best practice approach to electroplating systems control. This carefully curated assessment is the result of OEMs, Tier 1s, Plating applicators and Chemical Suppliers coming together and combining their points of view to push the industry forward.

Contact us today to discuss how we can help you turn your quality control challenges into a competitive advantage.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.