7 Tips for Achieving the Perfect Satin Finish on Metals

September 24, 2025

September 24, 2025

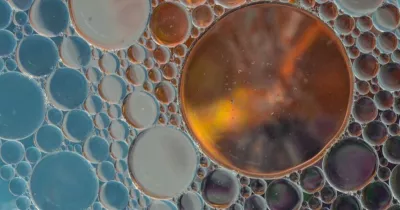

A satin metal finish strikes the perfect balance between the glossy sheen of a bright polish and the flat look of a matte surface. Its low-gloss, elegant appearance is a popular choice in industries from automotive and electronics to high-end hardware and fixtures.

But how is this sophisticated finish achieved? It’s important to clarify: we’re not talking about a satin paint. In the world of professional metal finishing, a true satin look is an integral part of the metal’s surface, achieved through a specialized electroplating process. This method provides a durable, consistent, and beautiful finish that paint simply can’t replicate.

Whether you're an engineer, a specifier, or a custom coater, achieving the perfect satin finish requires precision and expertise. Here are 7 essential tips to get it right.

1. Flawless Finish Starts with a Flawless Surface

The golden rule of metal finishing is that the final result is only as good as the initial surface. Before the plating process even begins, the substrate must be meticulously cleaned and prepared. Any oils, soils, or existing imperfections on the surface can lead to poor adhesion, blemishes, or an inconsistent final appearance.

Pro-Tip: A robust pre-treatment process is non-negotiable. Utilizing a high-quality line of metal cleaners ensures the surface is perfectly prepared for plating. For more information on preparing your parts, explore our Pre-Plate Solutions.

2. Use a Specially Designed Plating Solution

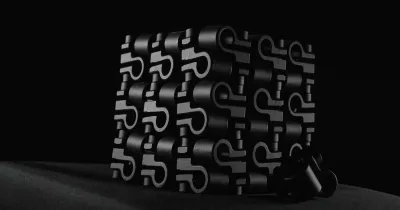

You can’t achieve a true satin finish with a standard bright nickel bath. The secret lies in using an electroplating solution specifically formulated to create that soft, uniform sheen. A satin nickel plating solution is the industry standard, containing special additives that control the grain structure of the deposit, resulting in a low-gloss, decorative look.

3. Carefully Control Your Brighteners

In traditional plating, brighteners are used to create a brilliant, mirror-like finish. For a satin effect, the opposite is required. The finish is achieved by using a chemical formulation with little to no brighteners, or by introducing specific additives that interrupt the crystal growth on a micro-level, scattering light to create that signature satin appearance. This precise chemical balance is key to avoiding unwanted shine or dull spots.

4. Master Your Current Density and Agitation

Achieving a uniform satin finish across an entire part, especially one with complex geometry, requires tight control over the electroplating parameters. The electrical current density must be optimized and stable, while bath agitation must be consistent. Improper control can lead to streaking or variations in reflectivity, compromising the desired outcome.

5. Consider Other Satin & Matte Finishes

While satin nickel is the most common, the same principles can be applied to achieve beautiful matte finishes with other metals. Matte copper, tin, or even alloy coatings can be produced through carefully formulated chemistry. This opens up a world of aesthetic possibilities for different applications and design requirements.

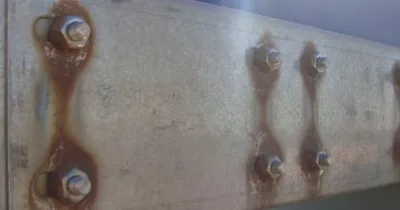

6. Protect Your Work with a Post-Treatment

Once you've achieved that perfect satin look, you need to protect it. The right post-treatment, such as a trivalent chromium plating system like Decotri or Hex-A-Gone and clear topcoat or sealer, is crucial for enhancing durability, improving corrosion resistance, and preserving the finish from fingerprints and wear. This final step ensures the finish remains as impressive as the day it was plated.

Don't let your hard work go to waste. A high-performance topcoat is essential for durability. Discover how PAVCO's Post-Plate Solutions can preserve your finish.

7. Consistency is Key: Test and Collaborate

Finally, meeting specifications requires rigorous quality control. Regularly test for finish consistency, color, gloss level, and adhesion. Collaborating with a chemical supplier who understands the nuances of the entire process—from pre-treatment to post-treatment—can make all the difference. An expert partner can provide the technical support and innovative products needed to overcome challenges and achieve repeatable, high-quality results.

At PAVCO, we're more than a supplier; we're a partner in finishing. If you're looking to achieve a specific finish or optimize your plating process, contact our technical team today. We have the expertise to help you succeed.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.