Challenges and Future of Hard Chrome Plating in Modern Manufacturing

December 18, 2025

December 18, 2025

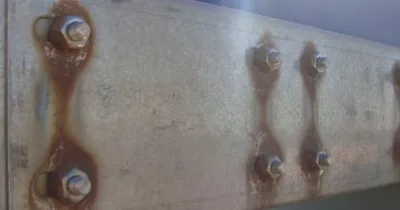

For decades, hard chrome plating (HCP) has been the gold standard in manufacturing, prized for its unparalleled combination of durability, hardness, and corrosion resistance. From aerospace landing gear to hydraulic cylinders, the functional coating has proven its worth in demanding applications. However, the industry is now at a critical inflection point. The very chemistry that gives HCP its strength—the use of hexavalent chromium (Cr(VI))—is also a recognized human carcinogen, leading to increasing environmental, health, and regulatory hurdles.

This article delves into the current challenges the hard chrome industry is facing, examines the economic and technical pressures driving change, and explores the high-performance alternatives that are defining the future of wear-resistant coatings. To stay informed on the latest regulatory changes, read this blog post.

The Regulatory and Economic Pressure on Cr(VI)

The primary challenge to hard chrome plating is the global tightening of environmental and occupational safety regulations. Cr(VI) compounds are highly toxic, and their use

necessitates stringent controls, which significantly increases compliance costs.

Key regulatory drivers include:

European REACH Controls: Strict limitations and phase-out requirements for Cr(VI) use across the European Union.

US EPA NESHAP Emission Limits: National Emission Standards for Hazardous Air Pollutants, requiring costly control technologies to limit Cr(VI) emissions.

State-Level Phase-Outs: Jurisdictions like California are planning outright phase-outs of Cr(VI) processes, forcing manufacturers to transition.

These pressures have led to industry consolidation, as smaller shops struggle to absorb the rising costs of compliance, specialized ventilation, and waste treatment. It is also crucial to consider the base metal compatibility to prevent issues like Galvanic Corrosion.

Technical Difficulties and Workforce Challenges

Beyond the regulatory landscape, the hard chrome industry faces inherent technical and operational difficulties:

Low Electrodeposition Rates: Increases processing time and energy consumption.

Poor Adhesion, Cracking, and Blistering: Requires meticulous pre-treatment and post-machining, increasing rework.

Costly Post-Machining: The inherent hardness of the deposit makes grinding and finishing expensive.

Dwindling Skilled Workforce: The specialized nature and health risks associated with Cr(VI) have led to a shortage of experienced platers.

These factors, combined with the moderate growth projections for the sector, create a compelling case for exploring alternative technologies that offer comparable performance with reduced environmental impact.

Viable Alternatives to Hard Chrome Plating

The search for high-performance, Cr(VI)-free coatings has accelerated innovation. Several alternatives are now mature enough to replace hard chrome in select applications, offering lower toxicity and, in some cases, superior wear resistance.

1. Trivalent Chromium

Trivalent chromium plating uses the less toxic Cr(III) state. While historically used for decorative finishes, modern formulations are achieving functional properties closer to HCP.

Benefit: Significantly lower toxicity and easier waste treatment.

Challenge: Deposits are generally thinner and may not yet match the extreme hardness of Cr(VI) in all functional applications.

2. Electroless Nickel (EN) Coatings

Electroless nickel, particularly those alloyed with phosphorus or PTFE, offers excellent corrosion resistance and uniform thickness, even on complex parts.

Benefit: Uniformity (no high-current density build-up), excellent corrosion protection, and can be heat-treated for high hardness.

Challenge: Lower inherent hardness than HCP unless heat-treated; may not be suitable for all high-wear applications.

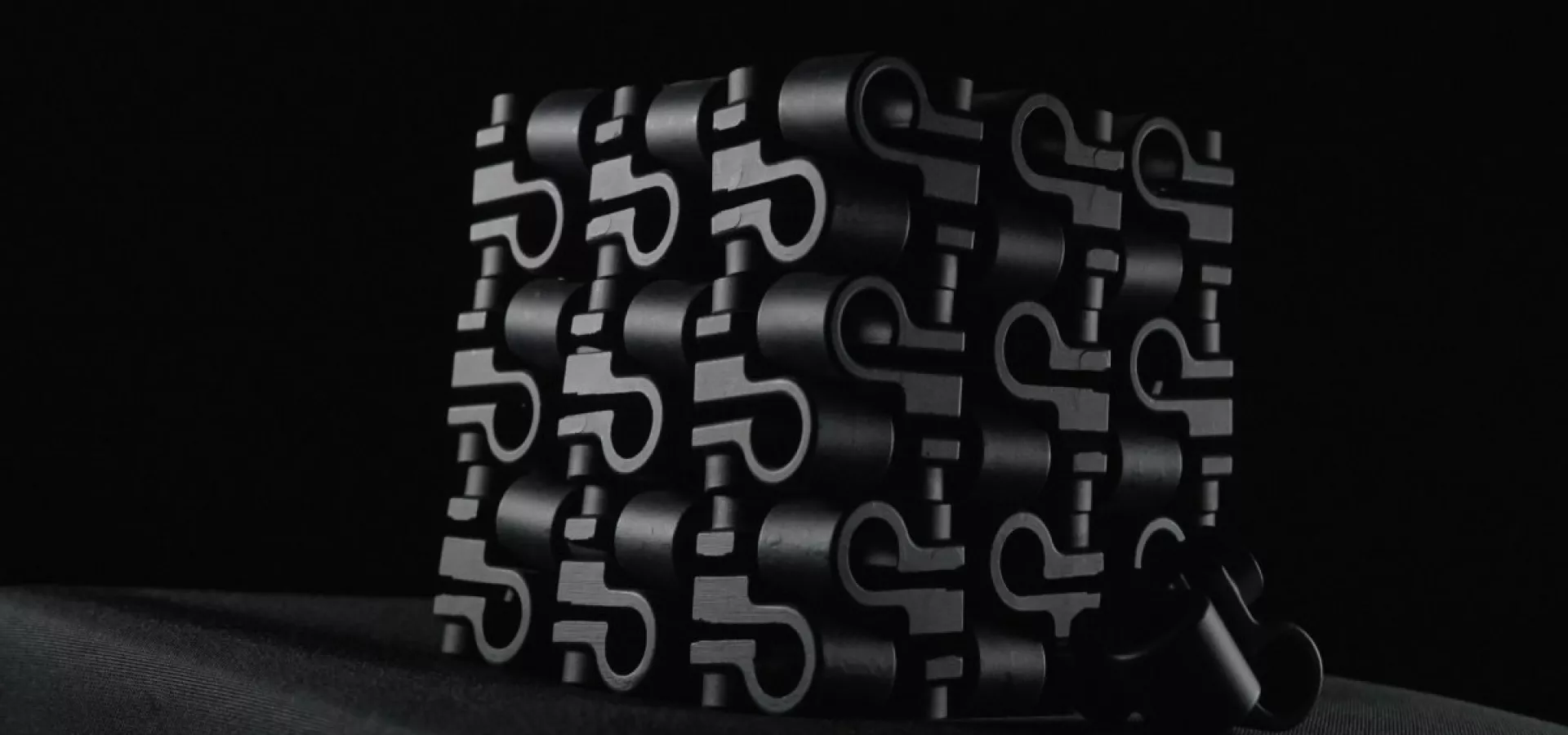

3. High Velocity Oxygen Fuel (HVOF) Thermal Sprays

HVOF is a process where powdered materials (like tungsten carbide or ceramics) are sprayed at supersonic speeds onto the substrate.

Benefit: Extremely dense, low-porosity coatings with superior wear resistance.

Challenge: Higher initial equipment cost; typically requires post-machining to achieve tight tolerances.

4. Nickel-Tungsten (NiW) and PVD Coatings

Nickel-Tungsten alloys and Physical Vapor Deposition (PVD) coatings are also gaining attention. NiW offers a combination of hardness and corrosion resistance, while PVD provides thin, extremely hard ceramic layers.

The future of Hard Chrome Plating

The future of hard chrome plating is one of specialization and replacement. While hexavalent chrome may sustain applications requiring unique specialization and low initial cost, the market is rapidly shifting towards greener, high-performance alternatives.

Manufacturers must proactively evaluate their needs and transition to solutions like trivalent chrome or Electroless Nickel to ensure regulatory compliance and long-term operational sustainability.

PAVCO is committed to helping manufacturers navigate this transition, offering cutting-edge solutions that meet the demands of modern engineering without the regulatory burden of hexavalent chromium. Explore Our Full Range of Solutions.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.