Hull Cell Test Method for Electroplating Solutions

April 01, 2025

April 01, 2025

Electroplating is an essential process that improves the look, durability, and corrosion resistance of metal surfaces. But how do you ensure the electroplating solution performs at its best? Enter the Hull Cell test—a simple yet powerful tool to analyze and optimize electroplating baths.

This guide will explain what the Hull Cell test is, why it’s important, and how Pavco’s industry-leading solutions can help you achieve outstanding results in your electroplating process.

What is the Hull Cell Test?

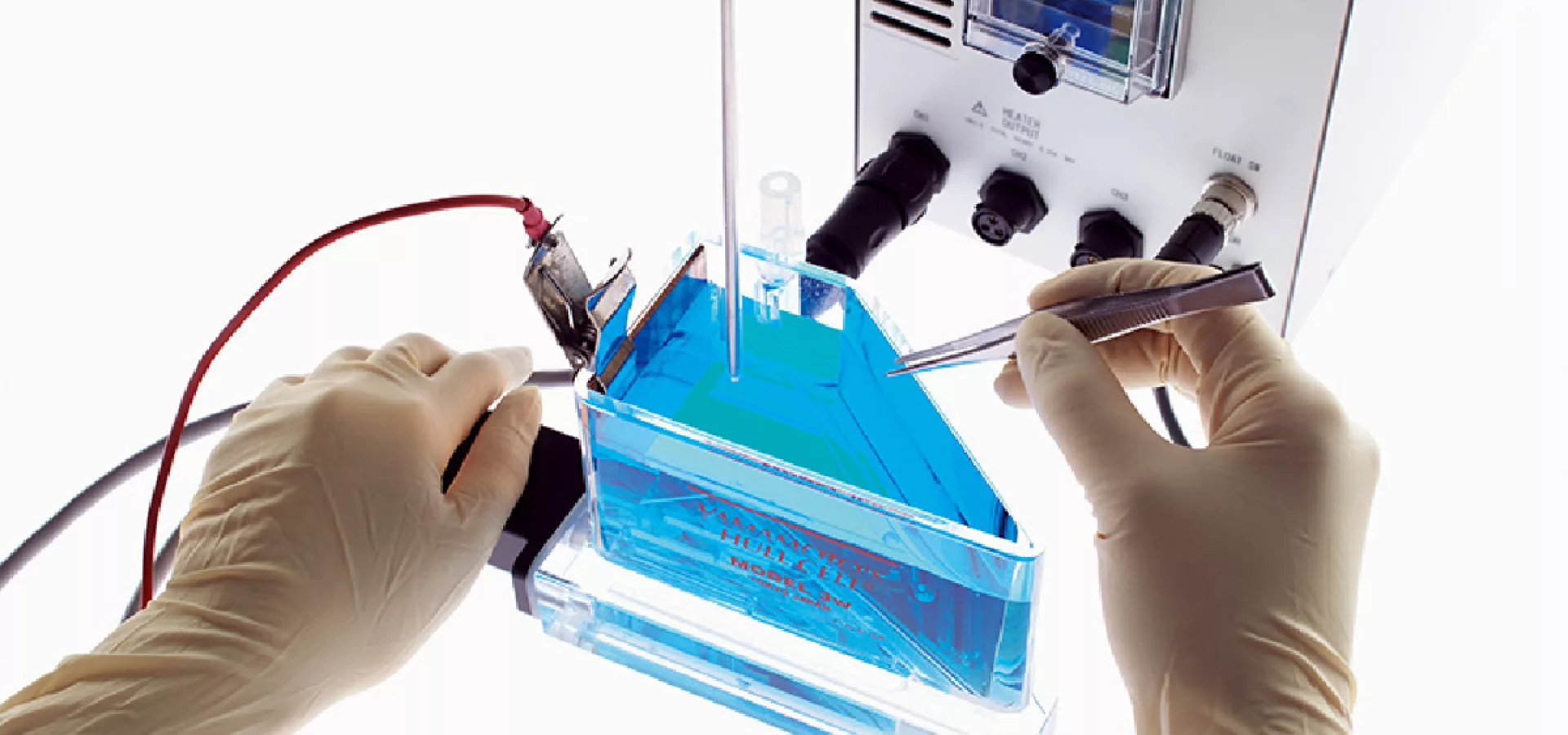

The Hull Cell is a diagnostic tool used to evaluate electroplating solutions by simulating real-world plating conditions in a lab environment. Its trapezoidal cell design ensures variable current density distribution across a test panel, making it an indispensable resource for understanding and improving your plating bath.

By testing a small sample of your plating bath, the Hull Cell can reveal issues like uneven coating, burning, or dullness, helping you achieve efficient processes and high-quality results.

Hull Cell Test Setup

The Hull Cell’s compact design includes a 267 mL solution capacity, an angled cathode panel set at 38°, and the ability to accommodate a wide range of current densities. Here's how you set up the Hull Cell:

Prepare the Solution: Use a sample of your plating bath. Ensure the solution matches the operating temperature, pH, and other important parameters of your full-scale process.

Position the Test Panel: Secure the angled cathode panel at the correct position ) to ensure even exposure to the solution.

Apply Current: Typically, 1–5 amperes of current is applied for a duration of 5–10 minutes. (See hull cell ruler for details)

This setup creates a gradient of current densities across the panel, allowing a comprehensive evaluation of your plating solution.

Conducting the Hull Cell Test

Here’s how the test works in practice:

Run the Test: Once the setup is complete, apply a controlled current to deposit metal onto the test panel.

Visual Analysis: After the test, examine the panel’s appearance to assess plating quality across various current densities. The visual results provide insights into issues like uneven deposits, pitting, burning, or dullness.

Scale Interpretation: Use overlay scales to correlate the position on the test panel to specific current densities. This helps identify where problems may arise in your full-scale plating process.(Hull cell ruler)

Documenting and Interpreting Results

To ensure consistency and track improvements over time:

Photograph Panels: Capture high-resolution images of test panels for reference.

Record Test Conditions: Document details like current, temperature, duration, and additives used during testing.

These records are essential for troubleshooting and optimizing your electroplating baths.

Problem Detection with the Hull Cell

The Hull Cell is a powerful tool for diagnosing problems, including:

Contamination in the bath

Improper solution composition

Additive imbalances

pH issues

Frequent testing—daily or weekly depending on bath usage—can catch problems early and prevent defects in your final product.

Also, if the hull cell is not showing the defects you are experiencing in the production line, you might need to experiment with current density, time, or other factors. Remember to use this tool in your favor so that you can replicate the problem in a small scale and establish a good strategy to fix it.

Complementary Testing Methods

While the Hull Cell is a key part of any quality control program, it works best when combined with:

Chemical Analysis: To verify the concentration of bath components.

Additive Testing: To ensure proper performance and adjust formulations as needed.

Together, these methods provide a complete picture of your plating solution’s health.

Why the Hull Cell Test is Crucial for Quality Control

The Hull Cell test ensures:

Consistent plating quality

Early detection of defects

Optimal solution performance

By integrating the Hull Cell test into your routine processes, you can maintain high standards, minimize waste, and improve efficiency.

Ready to Take Your Electroplating to the Next Level?

The Hull Cell test is a game-changer for optimizing electroplating baths, and with Pavco’s expertise and solutions, you’ll achieve unmatched results.

Since 1948, Pavco has been a trusted name in the metal finishing industry. Here’s how we can elevate your Hull Cell testing and electroplating processes:

Advanced Plating Solutions

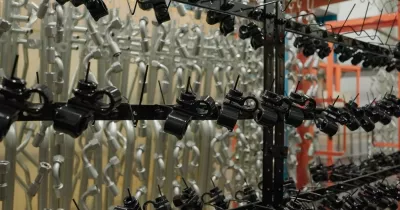

Pre-Plating solutions: Ensure flawless surface preparation for consistent results.

Innovative Plating Chemistries: Enhance durability, corrosion resistance, and appearance with our cutting-edge solutions.

Post-Plating Finishes: Add extra protection and aesthetic appeal with our trivalent passivates and topcoats.

Expert Testing Services

Custom Recommendations: Our experts help you interpret Hull Cell results and make tailored adjustments to your processes.

Ongoing Support: From training to troubleshooting, we’re here to help you succeed every step of the way.

Have questions or want to explore our products and services? Contact us today! Our team is ready to provide the insights and tools you need to achieve superior metal finishes.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.