What Are Anionic Surfactants and Why Are They Used in Metal Finishing?

September 24, 2025

September 24, 2025

In the world of metal finishing, achieving a perfect, durable, and high-quality result depends on chemistry. Every step, from initial cleaning to final coating, must be precise. One of the unsung heroes in this process is a class of molecules known as anionic surfactants. They play a critical, multi-faceted role in preparing metal surfaces and ensuring the final finish meets the highest standards.

But what exactly are they, and why are they so indispensable? Let's dive in.

What Are Anionic Surfactants?

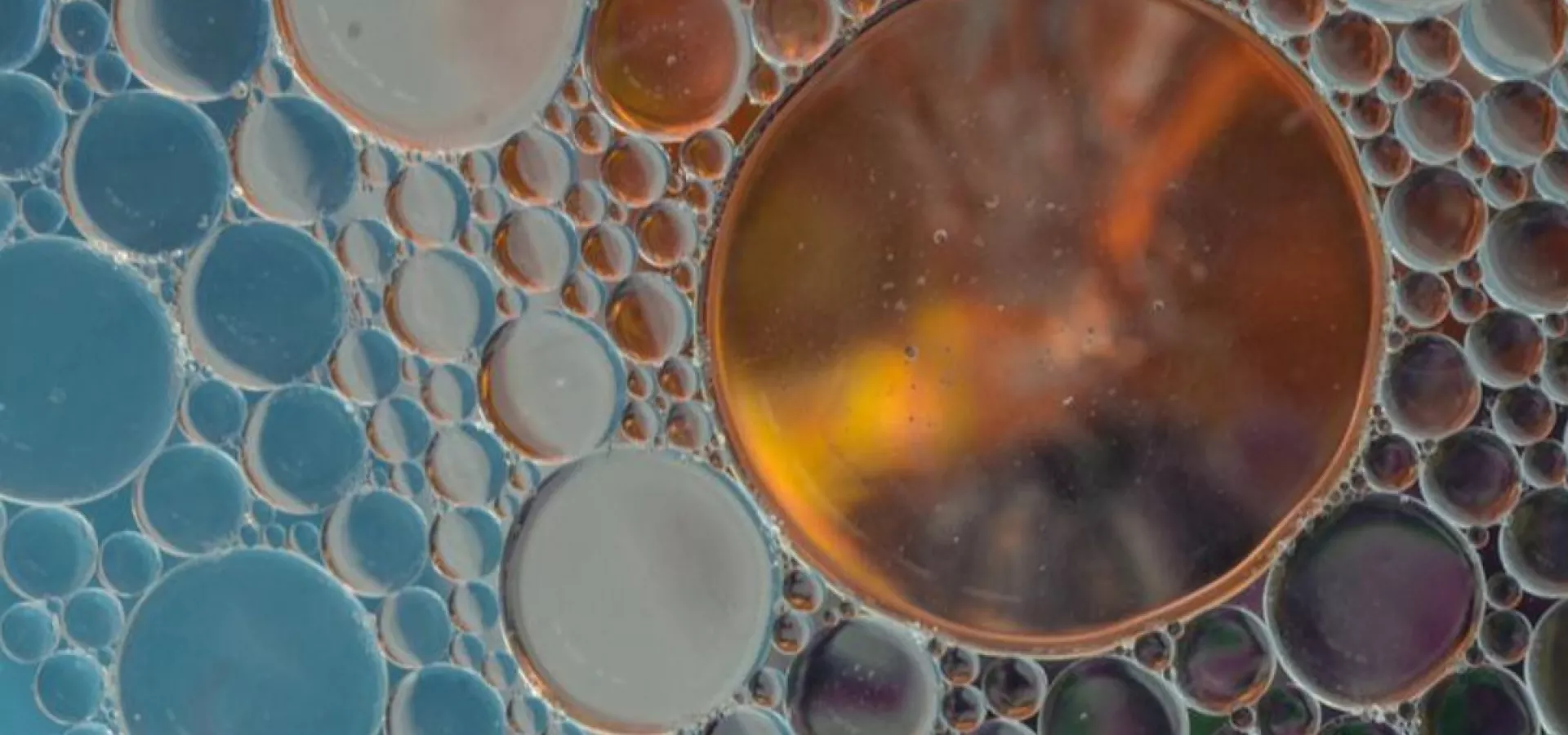

First, let's define a surfactant. A surfactant, short for "surface-active agent," is a compound that lowers the surface tension between two substances, like a liquid and a solid or two liquids that don't normally mix (think oil and water).

Anionic surfactants are a specific type of surfactant characterized by a negatively charged head group. You can think of the molecule as having a water-loving (hydrophilic) head with a negative charge and an oil-loving (lipophilic) tail. This unique structure is the key to their power, allowing them to effectively interact with and remove unwanted contaminants from metal surfaces.

Why Are They Used in Metal Finishing?

The unique properties of anionic surfactants make them essential for several key processes in the metal finishing industry. Their use leads to higher quality, better consistency, and more reliable results.

Enhanced Cleaning

The most common application for anionic surfactants is in cleaning and degreasing solutions. The oil-loving tails are drawn to oils, grease, and other soils on the metal's surface, while the water-loving heads pull these contaminants away from the metal and into the cleaning solution. This process, called emulsification, is fundamental for creating a perfectly clean surface, which is a prerequisite for any successful plating or coating application.

Wetting and Dispersion

For a finishing solution to work properly, it must cover the entire metal surface evenly. Anionic surfactants reduce the surface tension of processing baths, acting as powerful "wetting agents." This allows liquids to spread out smoothly across the metal, preventing beading, blotches, or untreated spots. They also help keep solid particles dispersed evenly throughout a liquid, ensuring a uniform and consistent finish.

Struggling with inconsistent finishes? The right chemistry makes all the difference. Contact a Pavco expert to discuss your specific needs!

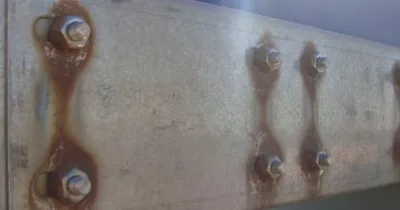

Corrosion Inhibition

Certain types of anionic surfactants are excellent corrosion inhibitors. They work by adsorbing onto the metal surface to form a thin, protective molecular layer. This barrier shields the metal from corrosive elements in the environment, like oxygen and moisture, effectively preventing rust and other forms of degradation during and after processing.

Enhanced Adhesion

Ultimately, the goal of metal finishing is to apply a new layer—whether it's plating, paint, or another protective coating. The success of this layer is entirely dependent on its ability to adhere to the base metal. By ensuring the surface is immaculately clean and free of any interfering contaminants, anionic surfactants create the ideal foundation for superior adhesion. A cleaner surface means a stronger, more durable, and longer-lasting finish.

The Foundation for a Flawless Finish

From cleaning to protection, anionic surfactants are a cornerstone of modern metal finishing. Their ability to manipulate surface chemistry ensures that every step of the process is optimized for the best possible outcome. Choosing the right surfactant formulation is key to achieving the performance, quality, and durability your project demands.

At Pavco, we specialize in advanced chemical solutions that drive results.Explore more about our innovative finishing technologies. Ready to elevate your finishing process?Schedule a consultation with our team today!

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.