Analyzing Plating Bath Components with High-Performance Liquid Chromatography

January 06, 2025

January 06, 2025

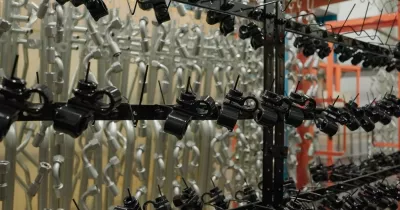

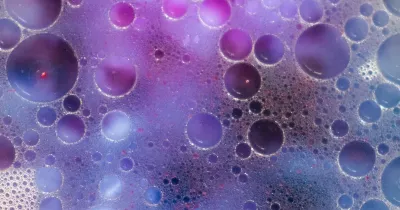

In the realm of electroplating, precision and control are paramount. The composition of plating baths, which are used to deposit metals onto surfaces, must be meticulously monitored to ensure optimal performance and product quality.

High-Performance Liquid Chromatography (HPLC) has emerged as a powerful analytical technique for analyzing and monitoring components in electroplating baths. This method offers several advantages over traditional techniques, providing more accurate and detailed information about bath chemistry.

In this article, we explore the capabilities of HPLC in analyzing plating bath components and how it enhances the electroplating process.

Key Components Analyzed by HPLC

HPLC can effectively analyze various components of plating baths, including:

Organic Additives: These include accelerators, brighteners, suppressors, and levelers. Each plays a crucial role in controlling the plating process, affecting factors such as deposition rate, surface finish, and uniformity.

Metal Ions: Essential for the electroplating process, metal ions must be present in precise concentrations to ensure proper deposition.

Electrolytes: These facilitate the flow of electric current through the plating bath, enabling the deposition of metal onto the substrate.

Contaminants and Degradation Products: Over time, contaminants can accumulate in the bath, and additives can degrade, affecting bath performance. HPLC can identify and quantify these substances, allowing for timely corrective actions.

Advantages of HPLC Analysis

Improved Accuracy and Precision

HPLC methods provide more accurate and precise measurements of plating bath additives compared to traditional techniques like Cyclic Voltammetric Stripping (CVS). This precision is crucial for maintaining the delicate balance of components required for high-quality plating.

Component Separation

HPLC can separate and identify individual components in complex mixtures, allowing for the detection of multiple additives and their derivatives. This capability is vital for understanding the interactions between different bath components and optimizing their concentrations.

Quantitative Analysis

The technique enables reliable quantification of additive concentrations, crucial for maintaining optimal bath performance. By providing precise measurements, HPLC helps in adjusting the composition of the bath to meet specific plating requirements.

Detection of Degradation Products

HPLC can identify and monitor the formation of decomposition species during the plating process. This capability allows for proactive maintenance of the bath, preventing potential quality issues in the plated products.

HPLC Methodology for Plating Bath Analysis

Sample Preparation

Plating bath samples are typically diluted and may require filtration or extraction depending on the specific components being analyzed. Proper sample preparation is essential for obtaining accurate and reliable results.

Chromatographic Conditions

Column: Reversed-phase columns are commonly used due to their ability to separate a wide range of compounds.

Mobile Phase: Often involves a mixture of water, organic solvents, and ion-pairing agents to optimize separation.

Detection: UV, conductivity, or charged aerosol detection (CAD) are frequently employed to detect various components.

Calibration

Standard solutions containing known concentrations of additives are used to create calibration curves for quantitative analysis. This step ensures that the HPLC system provides accurate measurements of component concentrations.

Applications and Insights

Additive Behavior

HPLC studies have revealed that brighteners often exist as a complex mixture of derivatives, while grain refiners tend to be in simpler forms. Understanding these behaviors helps in optimizing additive formulations for specific plating applications.

Additive Interactions

The technique can detect new species formed when different additives interact in the bath. This information is crucial for preventing adverse reactions that could compromise plating quality.

Process Monitoring

HPLC allows for tracking changes in additive concentrations and the formation of decomposition products during plating. This monitoring capability helps in maintaining consistent bath performance and product quality.

Bath Quality Control

By providing accurate measurements of additive levels, HPLC enables better control of the plating process, leading to improved product quality and reduced production costs.

Deep analysis for your plating bath chemistry

High-Performance Liquid Chromatography has proven to be an invaluable tool for analyzing and controlling plating bath chemistry. Its ability to provide detailed, accurate information about bath components enables better process control, higher product quality, and improved efficiency in electroplating operations.

For those in the electroplating industry seeking to enhance their plating processes, consider exploring the advanced solutions offered by PAVCO. With a history of innovation and a commitment to quality, we provide cutting-edge technologies and services designed to meet the evolving needs of the metal finishing industry.

Contact us now for personalized assistance.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.