How to Integrate Electrolytic Cleaning into Your Preplating Workflow

September 24, 2025

September 24, 2025

A flawless finish begins long before the plating bath. For any metal finisher, achieving superior adhesion, corrosion resistance, and a brilliant appearance is paramount. The secret? An impeccably clean substrate. While soak cleaners are a good first step, integrating electrolytic cleaning into your preplating workflow can elevate your quality and efficiency to the next level.

Electrolytic cleaning, or electrocleaning, is a powerful process that uses an electric current to remove stubborn soils that simple immersion cleaning might miss. If you're looking to reduce rejects and enhance the reliability of your finishing line, this guide will walk you through how to effectively integrate this crucial step.

What is Electrolytic Cleaning?

Electrolytic cleaning is an electrochemical process where a metal part is submerged in a specially formulated alkaline cleaning solution and subjected to a direct electric current. The part acts as an electrode in the circuit, and the electrical current causes two powerful cleaning actions:

Gas Scrubbing: The electrolysis of water at the surface of the part generates hydrogen or oxygen gas bubbles. These bubbles form rapidly, creating a vigorous scrubbing action that physically dislodges and lifts away tough contaminants like oils, grease, and fine particles.

Saponification: The alkaline solution reacts with oils and fats on the surface, converting them into water-soluble soaps—a process called saponification.

There are two main types of electrocleaning:

Direct Cleaning (Cathodic): The part is the cathode (negative electrode). This method produces a higher volume of hydrogen gas, resulting in more vigorous scrubbing. It's effective but carries a risk of hydrogen embrittlement in some high-strength steels.

Reverse Cleaning (Anodic): The part is the anode (positive electrode). It produces less gas (oxygen) but offers the advantage of de-plating trace metallic impurities and preventing the deposition of smut. This is the most common method for steel.

Integrating Electrolytic Cleaning into Your Workflow

Adding or optimizing an electrocleaning stage requires a systematic approach. Here’s how to do it right.

Step 1: Assess Your Needs and Select the Right Cleaner

The first step is to understand your specific application. Consider the base metal (e.g., steel, brass, zinc die-cast), the type of soil you need to remove, and your existing line configuration. The chemistry of your cleaner is the single most important factor for success. A cleaner designed for steel might be too aggressive for softer metals like brass or aluminum.

This is where partnering with an expert can make a significant difference. At PAVCO, we specialize in developing advanced cleaning chemistries tailored to specific substrates and operational needs. Our technical team can help you select a cleaner that delivers maximum performance without compromising the integrity of your parts.

Explore our range of specialized metal cleaners to find your perfect match.

Step 2: Configure Your Equipment

A typical electrocleaning setup includes:

A Tank: Usually made of mild steel.

A Rectifier: To supply the DC current.

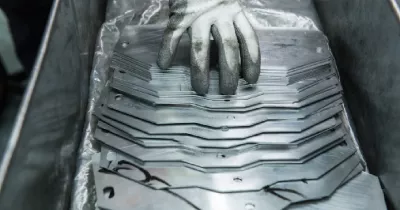

Electrodes: Steel plates or grids connected to the opposite pole of your part.

Ensure your tank is properly sized for your production volume and that the electrodes are positioned to provide a uniform current distribution across the workpiece. Poor configuration can lead to uneven cleaning.

Step 3: Dial in Your Operating Parameters

Once your setup is ready, you need to establish the optimal operating parameters. These four variables are key:

Concentration: Follow the supplier's recommendation. Too little cleaner will be ineffective, while too much is wasteful.

Temperature: Most electrocleaners operate in the range of 60−90circC (140−195circF). Higher temperatures increase cleaning speed but also energy costs.

Time: A typical cycle lasts from 30 seconds to 2 minutes. The goal is to achieve a "water break-free" surface, where a continuous sheet of water is maintained after rinsing, indicating a completely clean surface.

Current Density: This is a critical parameter, usually in the range of 5−15A/dm2 (50−150A/ft2). The right density ensures vigorous gassing without damaging the part.

Step 4: Position It in Your Preplating Cycle

Electrocleaning is not a standalone process. It must be correctly placed within the larger pre-treatment sequence for best results. A typical workflow looks like this:

Soak Clean → Rinse → Electrolytic Clean → Rinse → Acid Activation → Rinse → Plate

Each rinse step is just as critical as the cleaning itself to prevent dragging chemicals from one tank to the next, which can contaminate your baths and ruin your finish.

Additionally, some electroplaters benefit from what is commonly known as a double cleaning cycle. The objective here is to further improve cleaning of “hard to clean” substrates. The cycle looks like this:

Soak Clean → Rinse → Electrolytic Clean → Rinse → Acid Activation → Rinse → 2nd Electrolytic Clean → Rinse → 2nd Acid Activation → Rinse → Plate

Adequate rinsing after the first acid activation is crucial to minimize drag-in of chlorides into the 2nd electrocleaner. Chlorides tend to etch the parts during electrocleaning, an undesirable effect.

The Payoff: Why a Well-Integrated Process Matters

By effectively integrating electrolytic cleaning, you are investing in the quality and consistency of your entire operation. The benefits are clear:

Superior Adhesion: A microscopically clean surface ensures the plated layer forms a powerful, permanent bond with the substrate.

Enhanced Performance: A clean base metal is the foundation for achieving maximum corrosion resistance and durability.

Reduced Rejection Rates: By eliminating surface contaminants, you prevent common plating defects like blistering, pitting, and poor coverage, saving time and money.

Achieving these results consistently requires more than just the right chemicals; it requires a partnership. PAVCO is committed to providing not only industry-leading products but also the hands-on technical support to help you optimize your entire finishing process. Our experts can work with your team to troubleshoot issues and fine-tune your line for peak performance and efficiency.

Contact a PAVCO technical representative today to discuss your pre-treatment challenges.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.