How to choose the right metal cleaning solution for your project

April 30, 2024

April 30, 2024

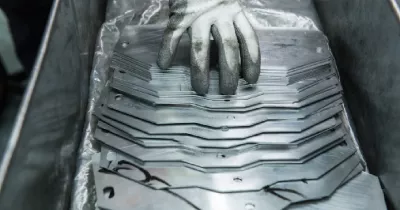

Cleaning surfaces for electroplating is a critical step in ensuring good adhesion and quality of the electroplated layer. The process typically involves several stages, starting with precleaning to remove the bulk of the soil, which can be done using solvents, emulsions, or alkaline sprays. This is followed by an intermediate alkaline cleaning and final electrocleaning to remove trace solids and especially adherent impurities. It's important to choose the right cleaners for your process depending on the metal to be cleaned and the soils to be removed.

Identifying the enemies

The first step in your cleaning crusade is to identify the primary contaminants you're facing. Common foes in the metalworking arena include:

Rust: This reddish-brown layer, a result of iron oxidation, compromises the structural integrity of metal.

Oil and Grease: These slippery substances, often introduced during machining or manufacturing processes, hinder adhesion and can interfere with subsequent finishing steps.

Embedded particles: The porosity of a metal substrate can house foreign particles that need to be removed to avoid issues in finishing steps. Also, excess carbon within those pores can interfere with adhesion of an electroplating layer.

Metal cleaning: A spectrum of needs

The level of cleanliness required for your project will also influence your cleaning solution choice.

For instance, if you're preparing a surface for plating, a high degree of cleanliness is essential to ensure a flawless, adherent finish.

Here's a breakdown of the main categories:

Alkaline cleaners, also known as basic cleaners, have a pH greater than 7. They are particularly effective in removing oils, greases, and other organic contaminants.

Acidic cleaners, conversely, have a pH less than 7. They are adept at removing rust, tarnish, and other inorganic contaminants. However, acidic cleaners can also be corrosive to the substrate and should have limited exposure.

Neutral cleaners, with a pH of 7, are the gentlest option. They are suitable for cleaning delicate metals and surfaces that are sensitive to alkaline or acidic solutions. However, neutral cleaners may not be as effective against certain contaminants.

Understanding metals, then cleaning them

When we talk about metals, we are talking about a wide range of materials, each with its own characteristics and behavior.

Each of these metals demands a specific approach to cleaning due to their inherent properties and susceptibility to different contaminants.

- Steel: Most commonly electroplated metal, its wide availability, low cost, and engineering properties makes it applicable to almost any industry. Strong alkaline cleaners are suitable for removing soils from the surface while strong acids like Hydrochloric acid can also be used to micro etch the surface. It is recommended to use an inhibitor to avoid excessive dissolution of Fe in this acidic stage.

Aluminum: Renowned for its lightweight and corrosion-resistant properties, aluminum is extensively used in aircraft, construction, and automotive applications. For effective cleaning of aluminum, mild alkaline or neutral solutions are typically employed to gently remove oxides without corroding the underlying metal.

Brass: An alloy of copper and zinc, brass is valued for its warm, golden hue and malleability. To restore brass's brilliance, slightly acidic cleaning solutions are often used to dissolve tarnish without affecting the metal itself.

Copper: Prized for its excellent electrical conductivity and thermal properties, copper finds widespread use in electrical wiring, plumbing, and cookware. To combat impurities, acid or alkaline cleaning solutions are used, depending on the severity of the impurities and the desired gloss level.

Nickel: Renowned for its corrosion resistance and silvery appearance, nickel is frequently used in plating applications to protect underlying metals. Mild alkaline or neutral cleaning solutions are generally effective in restoring nickel's luster.

By carefully considering the type of metal and the appropriate level of acidity, one can select the optimal cleaning solution to achieve effective cleaning without compromising the integrity of the metal substrate.

Unlock quality with Pavco’s metal cleaners

When it comes to preparing metals for plating, precision and efficiency are paramount. Pavco’s range of pre-plate cleaners ensures your metals receive the royal treatment they deserve. Let’s explore the options:

- Powdered Cleaners:

Clean-R1002 NC: A granular, alkaline soak cleaner powerhouse that tackles heavy-duty cleaning without compromising metal integrity.

Clean-R2002 NC: powdered, non-chelated, and perfect for ferrous metals, this electro cleaner means business.

- Splitting Liquid Cleaners:

Lectro NA: Concentrated electro-cleaner package for maximum detergency.

Paragon: A powerful liquid cleaner that leaves no room for compromise.

- Emulsifying Liquid Cleaners:

Clean-R235: Concentrated and gentle, this alkaline soak emulsifying cleaner ensures impeccable surfaces.

- Surfactant Only Packages:

Clean-R90 LS: Concentrated surfactant goodness for pristine results.

- Acid Salts & Additives:

PavHib: Extend the life of hydrochloric and sulfuric acid pickles economically and effectively.

Why choose Pavco? Our cleaning solutions are meticulously designed, ensuring your metals are impeccably prepared for plating. Whether you’re dealing with heavy-duty grime or delicate surfaces, Pavco has you covered.

Make the smart choice—choose Pavco for unmatched quality and efficiency.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.