Is Metal Blackening the Right Finish for Your Project?

September 24, 2025

September 24, 2025

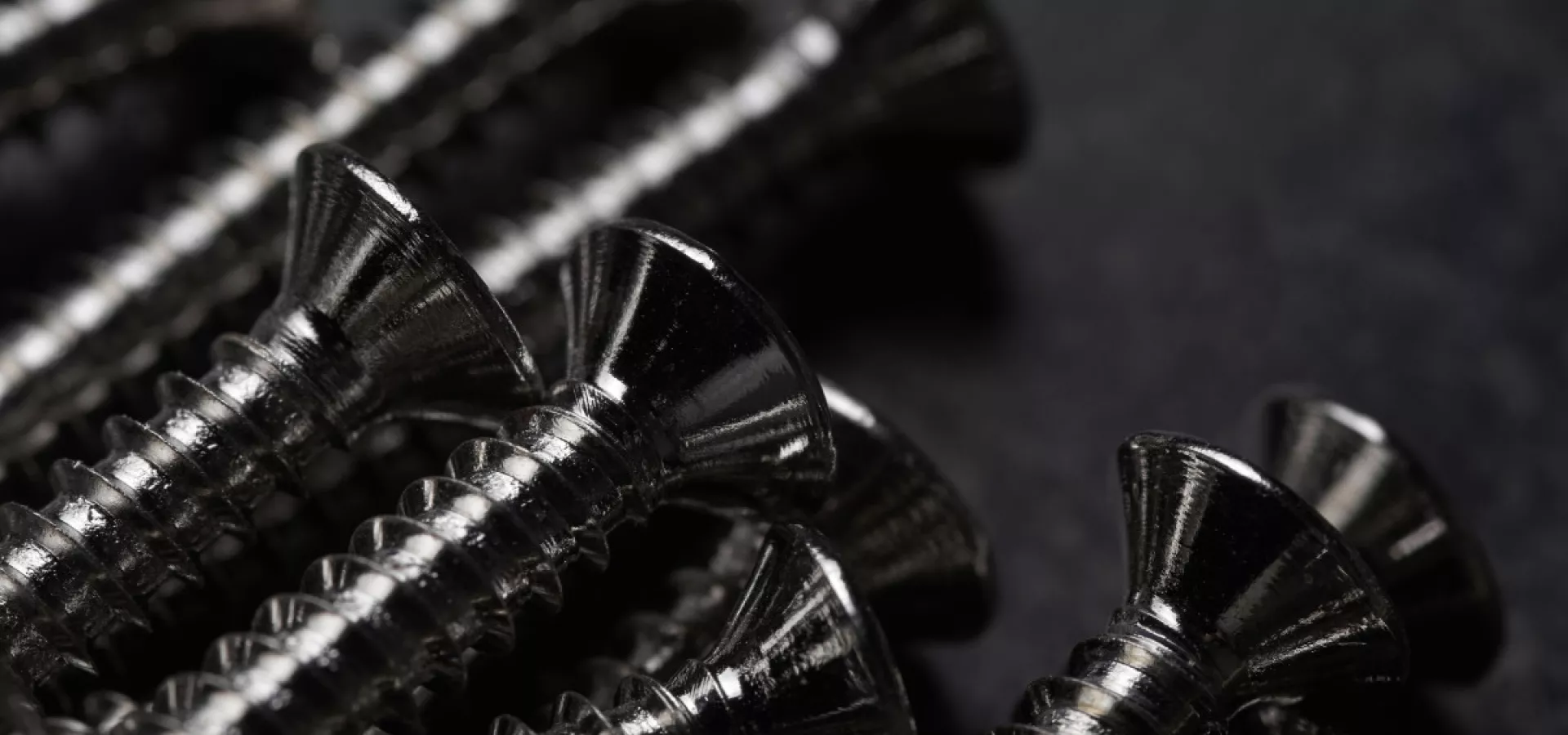

When it comes to metal finishing, a deep black look offers a classic, sleek, and high-performance aesthetic. But achieving that perfect black finish involves more than just color. The process you choose—known as metal blackening—has a significant impact on corrosion resistance, dimensional tolerance, and cost. Two of the most common methods are black oxide and black passivation.

So, how do you know which metal blackening process is right for your specific application? Let's break down the differences to help you make an informed decision.

The Classic Choice: Black Oxide

Black oxide is a chemical conversion coating specifically for steel. The process transforms the surface of the metal into a thin, durable layer of black magnetite (Fe_3O_4). It’s not a layer of paint or plating; it’s an integral part of the metal itself.

Here are the key characteristics of black oxide:

Appearance: Provides a matte to satin black finish that cleanly follows the base metal’s original texture.

Corrosion Protection: Offers minimal inherent corrosion protection on its own. Its effectiveness depends heavily on a post-treatment, such as an oil or wax coating, which seals the porous magnetite layer.

Dimensional Change: The change is negligible. This makes black oxide an excellent choice for projects with tight tolerances and high-precision parts where even a small change in dimension is unacceptable.

Cost: It is a very low-cost metal blackening option.

Maintenance: Light rust can often be removed with very fine abrasive material and oil, restoring the finish.

The High-Performance Option: Black Passivation

Black passivation is a different kind of metal blackening process. It involves applying a chromate conversion film over a layer of zinc or zinc-nickel plating. This multi-step process offers a robust finish that is both visually appealing and highly durable.

Key characteristics of black passivation include:

Appearance: Produces a more uniform, deep black color. It can be sealed to create a satin or slightly glossy finish.

Corrosion Protection: Delivers strong corrosion protection. The underlying zinc or zinc-nickel plating provides sacrificial protection to the base metal, meaning the plating will corrode first, significantly extending the part's lifespan.

Dimensional Change: The plating process adds measurable thickness to the part, which must be accounted for in the initial design.

Cost: The cost is higher due to the multiple steps involved (plating and passivating).

Maintenance: Clean with mild detergent and water. It's crucial to avoid harsh alkalis, strong acids, and heavy abrasives, as they can strip away the protective black film.

Need help determining the best finishing process for your components? Schedule a consultation with a Pavco finishing expert today!

Which Metal Blackening Finish Should You Choose?

The right choice depends entirely on your project's priorities.

Choose Black Oxide if: Your primary needs are a true-to-spec dimension, a specific aesthetic, and cost-effectiveness, and the part will be used in a low-corrosion environment or can be regularly maintained with oil. It is the go-to for fasteners, tooling, and precision components.

Choose Black Passivation if: Superior corrosion resistance is your top priority, and a slight increase in part thickness is acceptable. It's ideal for components exposed to harsh environmental conditions where durability is paramount.

The Final Word on Metal Blackening

Both black oxide and black passivation deliver an excellent black finish, but they serve different functional purposes. By understanding the key differences in protection, dimension, and cost, you can select the perfect metal blackening solution to ensure your project not only looks great but also performs flawlessly.

At Pavco, we specialize in advanced surface finishing technologies. Explore our full range of services to see how we can enhance the durability and appearance of your products. Contact us today to get a quote!

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.