Avoid Plating Failures: How to Perform a Proper Water Break Test

July 24, 2025

July 24, 2025

Plating is a critical process in the metal finishing industry, ensuring durability, corrosion resistance, and aesthetic appeal. However, achieving a flawless plated surface requires meticulous preparation, particularly in cleaning the substrate. One of the most effective methods to verify surface cleanliness is the Water Break Test. This simple yet powerful test can prevent plating failures caused by contaminants like grease and oils.

In this blog, we’ll explore why the water break test is essential, how to perform it correctly, and the standards that govern its application.

Why is the Water Break Test Important?

The success of any plating process depends on the bond between the plating material and the substrate. Contaminants such as grease, oils, or other hydrophobic residues can compromise this bond, leading to issues like foggy patches, uneven plating, or even complete adhesion failure.

When contaminants are present, they interfere with the surface's ability to interact with plating solutions, resulting in poor adhesion. This is where the water break test becomes invaluable. It allows platers to detect the presence of hydrophobic contaminants quickly and non-destructively, ensuring the substrate is clean and ready for plating.

What is the Water Break Test?

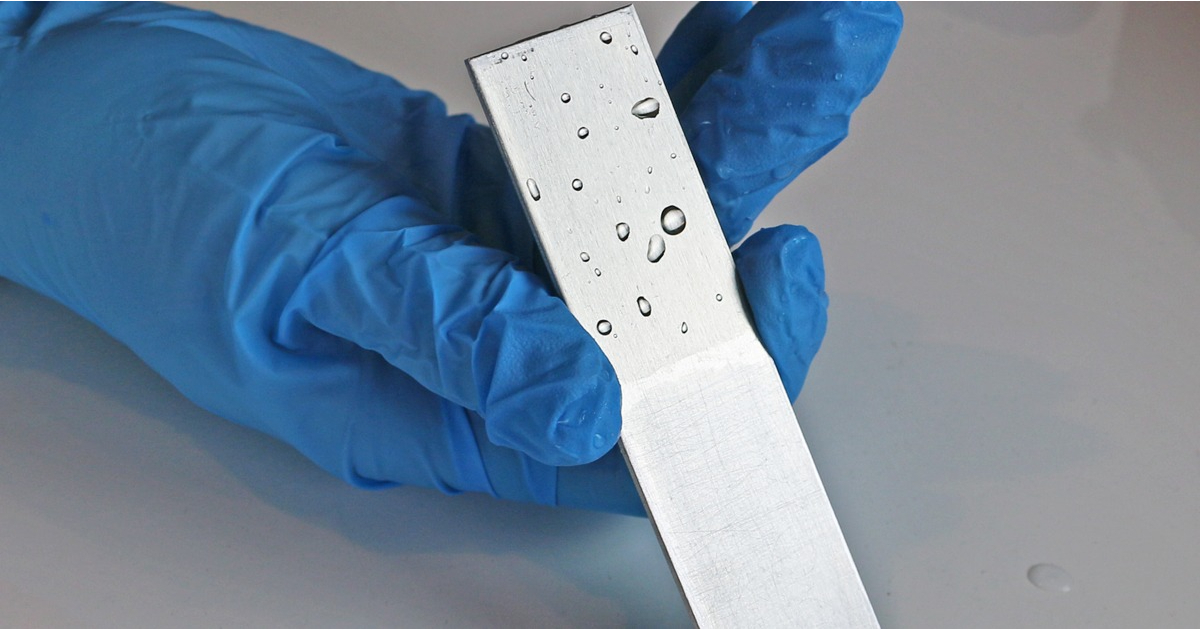

The water break test is a straightforward procedure used to evaluate the cleanliness of a surface. It involves observing how water behaves when applied to the substrate. A clean surface will allow water to form a continuous film, while a contaminated surface will cause the water to bead up or break into droplets.

This test is particularly useful for detecting hydrophobic contaminants, which repel water and disrupt the formation of a continuous water film. It is commonly used in industries such as aerospace, automotive, and electronics, where surface cleanliness is critical for processes like plating, priming, and adhesive bonding.

You may want to read: Choosing the Best Cleaner for Optimal Surface Preparation

How to Perform the Water Break Test

Performing the water break test is simple, but precision and attention to detail are essential. Here’s a step-by-step guide:

1. Prepare the Surface

Ensure the substrate has undergone preliminary cleaning to remove visible dirt and debris.

Use appropriate cleaning agents such as alkaline cleaners or solvents to remove oils and grease. Rinse thoroughly with deionized water to avoid introducing new contaminants.

2. Apply Water

Hold the substrate under running water or use a clean spray bottle to apply a thin, even layer of water to the surface. For small objects, dipping the item in water can also be effective.

3. Observe the Water Behavior

Carefully observe how the water interacts with the surface:

Clean Surface: Water forms a continuous, unbroken film.

Contaminated Surface: Water beads up, breaks into droplets, or flows unevenly.

4. Interpret the Results

If the surface fails the water break test (i.e., water beads up), additional cleaning is required. Repeat the cleaning process and test again until the surface passes.

5. Document the Results (Optional)

For quality assurance purposes, document the test results, including photographs of the water behavior and any corrective actions taken.

Standards Governing the Water Break Test

The water break test is recognized in several industry standards, ensuring consistency and reliability in its application. The most notable standard is ASTM F22-02, which outlines the procedure for detecting hydrophobic surface films.

Key Points from ASTM F22-02:

The test is rapid, non-destructive, and suitable for in-process verification of surface cleanliness.

It is not a quantitative test but serves as a go/no-go evaluation of cleanliness.

The standard emphasizes the importance of using clean water and avoiding contamination during the test.

Other standards, such as MIL-C-53072 for Chemical Agent Resistant Coatings (CARC), also reference the water break test as a method for verifying surface cleanliness.

Ensure Perfect Plating with Proven Surface Prep

The water break test is a straightforward yet essential method for verifying surface cleanliness prior to plating. By identifying hydrophobic contaminants, this test helps prevent adhesion failures, ensuring a smooth, consistent finish and long-term product performance. When combined with standards like ASTM F22-02 and sustainable cleaning practices, it becomes a powerful tool for quality assurance and environmental responsibility.

At PAVCO, we’re dedicated to advancing the science of surface preparation. Our solutions are engineered to help you meet the highest quality and sustainability standards—without compromise.

Need help optimizing your pre-plating process? Get expert guidance from our technical team and make sure every surface is plating-ready.

Looking for sustainable, high-performance technologies? Explore PAVCO’s innovations in surface prep and plating chemistry designed to support cleaner, more efficient operations.

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.