Why are your testing results inconsistent? | Analytical and Salt Spray Testing

June 10, 2022

June 10, 2022

I will start this by dividing it up into two sections that I am very familiar with in the electroplating industry; analytical testing results and salt spray testing results. Electroplating is one of the most popular processes in metal finishing and is used in a wide range of industries for various purposes.

Despite the popularity and high demand of electroplating, very few companies outside of the industry are familiar with the process, what it is and how it works. If you’re considering using electroplating in your next manufacturing process, reach out to PAVCO.

Our history started back in 1948, and it stands behind the quality of our products. Learn more about our plating technologies here.

The types of tests for metal finishing products

Using a salt spray test is putting all your products to the test. And while there are different types of salt spray and many are meant to simulate certain hostile environments, there are also ways to analyze the plating baths and supporting chemical solutions.

Analytical testing

Common Problems/solutions:

- Two different analysts are getting very different results on the same test.

- Is the solution the same temperature when pipetting?

Cold liquids tend to be delivered in excess quantity, while warm liquids tend to be under-delivered.

- Are both pipettes or TD or TC? Are they using the pipette correctly?

TD- means to deliver and the delivered quantity of liquid corresponds to the capacity printed on the pipette.

TC- means to contain and you must blow out any residual liquid left in the pipette.

- Are the analysts going to the same endpoint?

Check for color change and/or pH.

- Is the solution the same temperature when pipetting?

- Large spike or decrease in results from one day to the next.

Check to ensure what was added to the plating bath.

Check Auto-feeders

- Is the plating tank’s level adequate?

Is there a leak in the tank?

- Check titrants and indicator’s expiration dates to ensure quality and strength.

Standardize titrants to guarantee correct Normality or Molarity.

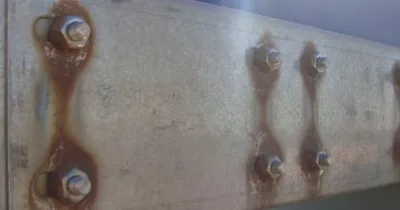

Salt Spray Testing

Common Problems/solutions:

- Run one set of parts one month and they pass. Next month the exact same parts are showing some failures. Note that corrosivity can vary in the same cabinet up to 20%.

Verify collection rates, spG, pH of salt solution daily, titrate for chlorides

Were parts placed in the same area of the cabinet (are you rotating parts to ensure they are receiving uniform fog)?

- Part handling/packaging after processing

Parts should be handled with gloves to avoid oils/contamination

- Use the correct packaging material

Acid free tissue paper

Avoid use of plastic bags, they trap moisture and become mini humidity chambers.

- Different testing results between labs

- All the above factors come into view when looking at results between different labs. Corrosivity between cabinets can vary up to 36%.

Collection rates from 1-2 ml. per hour.

Angle (15-30%) and placement in cabinet (Are parts touching walls, parts parallel to salt fog flow, spacing between parts, mounting materials)?

Part handling (Are the operators wearing gloves)?

- All the above factors come into view when looking at results between different labs. Corrosivity between cabinets can vary up to 36%.

It is important to look at all of these factors when considering why you are getting inconsistent testing results. Some of these solutions are very simple fixes, while others may take a bit more investigation to determine the root cause.

Pavco is a company with more than 75 years of experience in the metal finishing industry. Learn more about our global and U.S. presence.

It’s how you finish!

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.