How to achieve a clear coat for metal parts

April 30, 2024

April 30, 2024

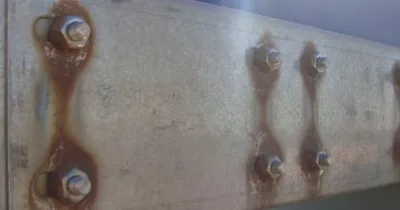

In the realm of metalwork, a clear coat stands as an invisible shield, safeguarding the underlying metal from the ravages of time and enhancing its visual appeal.

This transparent layer, applied as the final touch, serves as a barrier against corrosion, scratches, and other forms of damage, ensuring that metal parts retain their pristine condition and aesthetic charm.

What is a Clear Coat for Metal?

A clear coat for metal refers to a transparent layer applied over a metal surface. This acts as a protective barrier, shielding the metal from environmental elements like moisture, UV rays, and corrosion.

However, for specific applications like zinc and zinc nickel plating, achieving a clear coat involves a more nuanced approach. Here, a clear finish relies on a two-step process:

Passivation: This step involves creating a thin, invisible film on the metal surface. This film acts as a barrier against corrosion and, when formed correctly, appears completely clear, enhancing the natural beauty of the metal.

Sealer/Topcoat (optional): While passivation offers a clear coat, some applications might require an additional layer of protection. This is where clear sealers or topcoats come in. They provide an extra layer of defense against scratches, wear, and environmental factors.

Step One: Passivation

Passivation involves creating a thin, invisible film on the metal surface that acts as a barrier against corrosion. This film, when formed correctly, appears completely clear, enhancing the natural beauty of the metal.

Several factors influence the clarity of the passivation layer:

pH: A lower pH solution (more acidic) can lead to a thicker passivation layer, essential for achieving a clear finish.

Temperature: Increasing the bath temperature can also promote a thicker, clearer passivation layer.

Immersion Time: Extending the immersion time in the passivation solution allows for a more robust and clear film to develop.

How to avoid a light blue film

Sometimes, a thin, light blue film appears on the metal after passivation. This indicates a very thin layer. To achieve a clear coat, you can:

Modify the pH: As mentioned earlier, a slightly acidic solution can help create a thicker, clear film.

Adjust the bath temperature: A warmer bath can also promote a thicker layer.

adjust immersion time: Allowing the metal to stay in the passivation solution for 30 to 45 seconds longer can ensure a clear and protective film.

Selecting the Right Clear Passivation Product

Choosing the right passivation solution is an essential step in achieving a crystal-clear finish on your zinc or zinc nickel plated parts.

Pavco's HyProTec & HyProTec 291. These passivation champions are formulated specifically to excel in creating a clear, transparent layer on your electroplated surfaces.

Here's what makes them stand out:

Optimized Formulation: These products are designed to promote a thicker passivation layer compared to standard products. This thicker film is key to achieving a flawless, transparent finish.

Consistent Performance: These passivation solutions are formulated for consistent results, ensuring you get a clear finish across every batch of parts processed.

Wide Operating Range: HyProTec & 291 offer a versatile operating range, allowing you to achieve optimal results within a variety of plating parameters. This flexibility makes them ideal for various production environments.

Step Two: Topcoat

While passivation offers a clear coat, some applications might require an additional layer of protection. This is where clear topcoats come in, providing an extra layer of defense against scratches, wear, and environmental factors. They can also enhance the overall sheen or provide a matte finish, depending on the chosen product.

When selecting a clear topcoat, it's important to consider factors like desired finish (glossy vs. matte) and compatibility with your existing plating process. Here's where Pavco shines!

In fact, almost any HyProCoat can be an excellent solution for achieving a clear topcoat. HyProCoat sealers offer a variety of formulations to suit your specific needs, ensuring compatibility and optimal performance.

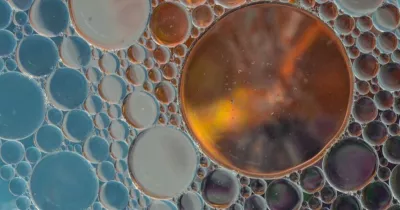

Avoiding Iridescence in Clear Topcoats

Iridescence, a rainbow-like effect, can sometimes occur with clear topcoats. Here's how to prevent it:

Concentration: Using the correct concentration of the topcoat solution is essential. A slightly higher concentration (1-5%) can sometimes minimize iridescence.

Temperature: Try increasing the temperature 10 to 20 degrees Fahrenheit.

By understanding these clear coat techniques for electroplating, you can achieve a flawless, transparent finish on your metal parts, enhancing their beauty and extending their lifespan.

Unsure which topcoat is right for your project?

With a variety of options available, selecting the ideal topcoat can seem daunting. Don't hesitate to contact PAVCO's team.

Contact us today to learn how we can elevate your finishing process. Unlock the full potential of your metal parts!

IT’S HOW YOU FINISH

We’re a developer and supplier of chemistries for the metal finishing industry since 1948.

In PAVCO, we develop products and deliver services of the highest quality at a reasonable cost.